Font reading on transparent packaging: With Deep Learning, OCR on difficult backgrounds is no problem.

Unlocking new horizons with AI

Intelligently confronting difficult inspection situations

Deep Learning as a tool for complex problems

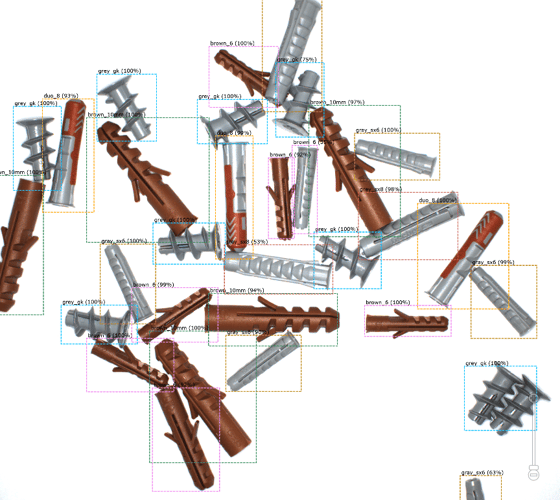

There is a wide range of tasks in machine vision that people solve intuitively, but which are difficult to describe parametrically. As a result, they cannot be solved by rule-based methods.

This includes the analysis of products with a wide range of features or non-separable characteristics. Deep Learning is also the method of choice for objects with transparent, reflective, curved or inhomogeneous surfaces.

The reason for this impressive capability is the self-learning aspect. A neural network is fed image data and the desired decisions. Using a large amount of this data, the system is able to determine a suitable solution path. The patterns and properties that lead to the decision are derived independently.

It is assumed that the decision path can be considered universal as the statistical variance of the input data increases. This makes it possible to apply the method accurately to the analysis of previously unknown data.

What kind of tasks does AI solve?

The strength of Deep Learning often lies in application areas where conventional, rule-based methods no longer offer any solution possibilities.

Typical application areas of AI include:

In borderline situations, AI is often the technological solution that makes automated handling possible in the first place - instead of opting for manual inspection procedures for reasons of safety and precision.

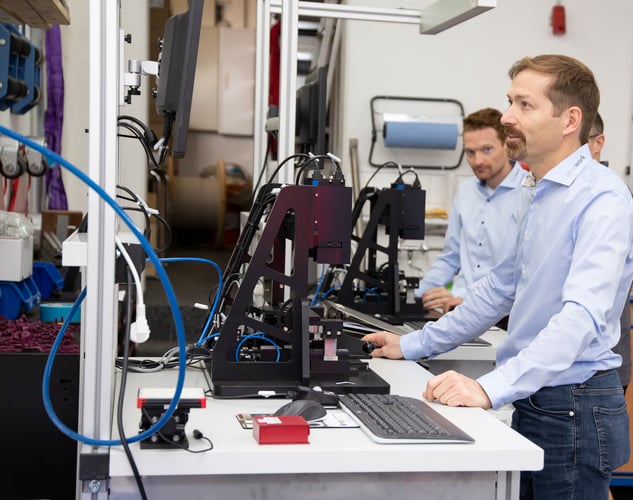

We integrate Deep Learning into your automation solution

Over the course of a decade, Deep Learning has evolved from an unimpressive approach in practice to an indispensable technology for demanding optical inspection tasks.

With our experience from numerous industrial projects and our expertise in machine vision, we develop the optimal AI solution for your production process - whether as a turnkey solution or process-accompanying.

When it comes to implementing AI applications, we offer a wide range of services tailored to your needs. We support you throughout the entire planning and implementation phase, right through to integration. Our services range from turnkey test machines, which we design and manufacture, to partial services for planning and integration, to consulting and training.

We are independent in our choice of tools and focus on the optimal technological solution. We use our own highly flexible Deep Learning platform Neuralyze as well as products from other well-known software vendors.

AI development as a service

We offer the development of customised AI models for your specific application as a service.

Whether you are new to this technology and want to build up your expertise with us, or you are an experienced AI user and want to leave the development and training of your models to machine vision experts, you will benefit from our experience of over a decade of successfully implemented application scenarios in industrial image processing and machine learning.

Our service model gives you the freedom to focus on your company's expertise and thus reach your goal faster with your AI application.

We monitor, maintain and train your model on an ongoing basis, ensuring that your production runs smoothly.

Integrate Vision AI into existing processes

Font reading on transparent packaging: With Deep Learning, OCR on difficult backgrounds is no problem.

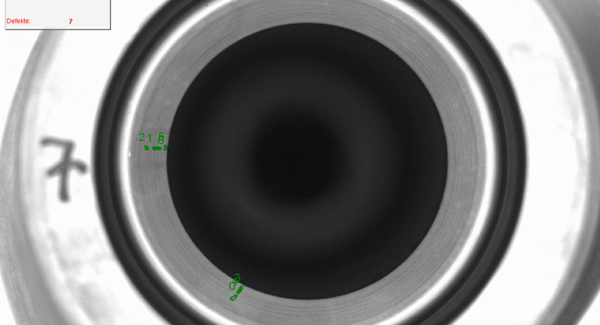

Efficient inspection of aluminium bodies: senswork's optical measuring system detects irregularities on the surface using AI.

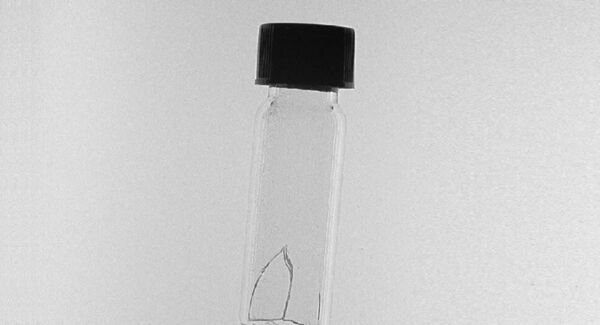

Learn how Deep Learning makes defect detection possible for reflective surfaces such as glass vials.

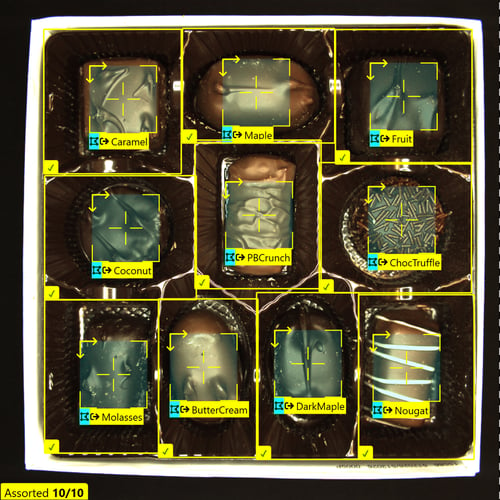

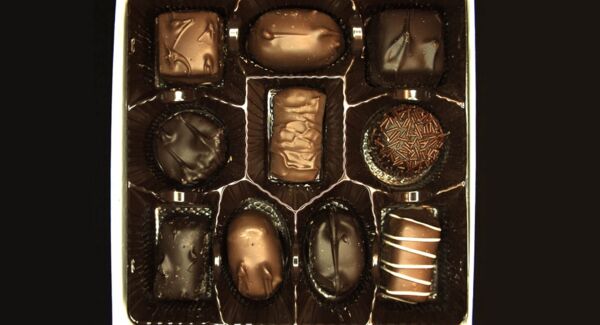

Detect the position and completeness of chocolate boxes. Deep Learning reliably detects even a large number of variants.

Efficient automation of laser welding of hairpins for electric motors with AI. 100 % inline inspection for optimal quality.

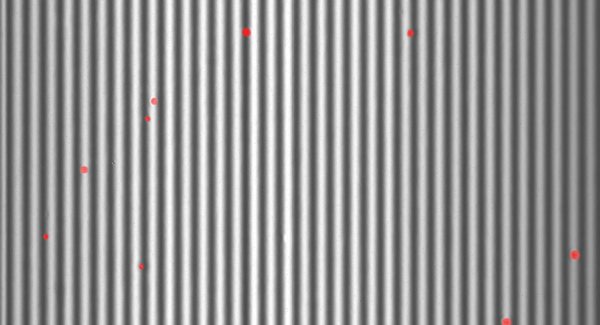

Learn how AI-based image processing from senswork detects bubbles, inclusions and defects in transparent sheets.

Guide

Industrial image processing and computer vision are constantly evolving. Deep Learning as a method of artificial intelligence represents a paradigm shift. The principle of automatically generating algorithms for recognizing features by labeling image data instead of defining explicit rules is particularly groundbreaking.

Markus Schatzl

Director

Innovation Lab

senswork GmbH

Friedenstraße 18

81671 München

Leave a message