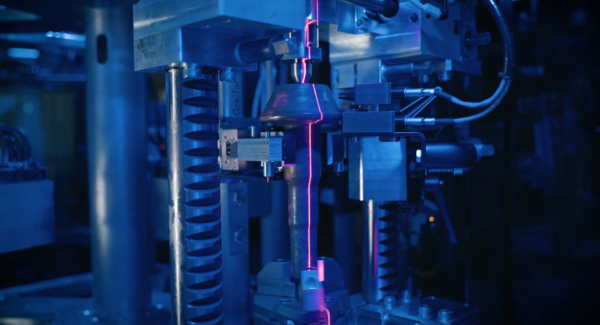

Automatic detection of surface defects

Surface InspectionOur solutions for optical surface inspection combine innovative image recording with precise image evaluation. This enables us to reliably detect a wide range of defects, including scratches, cracks, dents, chips, paint defects, contamination, color deviations and much more. Read more