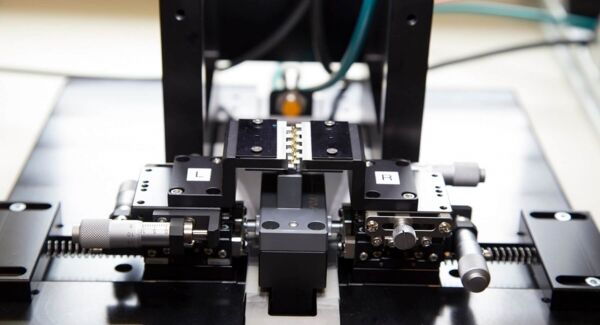

The senswork optical 2D metrology system ensures the correct feeding of microchips in the semiconductor industry. Discover the benefits.

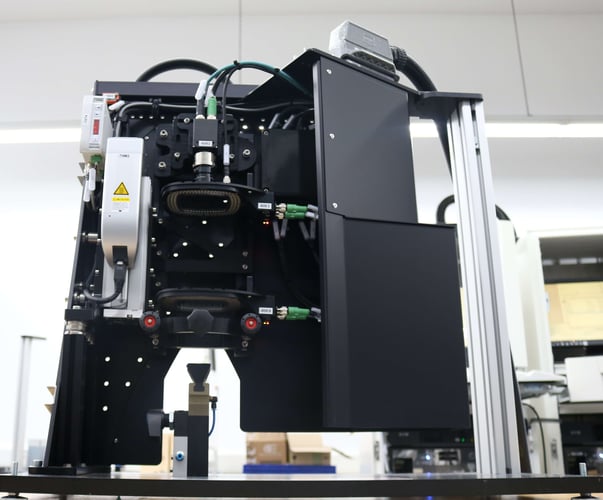

Plug-and-play machine vision module quick & easy to integrate into systems

Save time & effort with ready-to-install camera modules. The VisionUnit from senswork is ready for immediate use thanks to standardized interfaces.

Machines and systems can be quickly and easily enhanced by an optical testing unit for automated inspection: with the VisionUnit. The entire inspection technology fits into one module. This allows perfect utilization of what is optically possible, reliable inspection and fast integration. This saves time and money during commissioning.

With perfectly aligned testing technology

One module instead of many individual components

Thanks to standardized interfaces and default settings

Fast conversion, digital documentation

When planning machines and systems thanks to defined installation space

One machine vision module for multiple inspection tasks.

With the turnkey VisionUnit inspection system, various inspection tasks can be carried out automatically. The ready-to-install VisionUnit machine vision module can be individually equipped with inspection technology to suit the respective inspection task. It is ideal for the automated inspection of 5-100 mm components. Possible inspection tasks are for example:

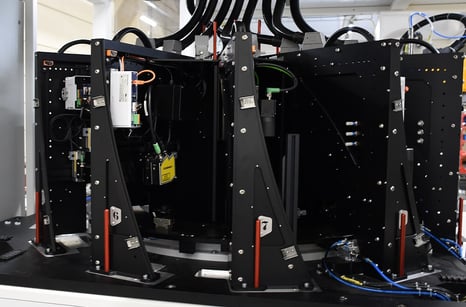

Cover multiple inspection tasks in the production process, for example in a rotary indexing machine.

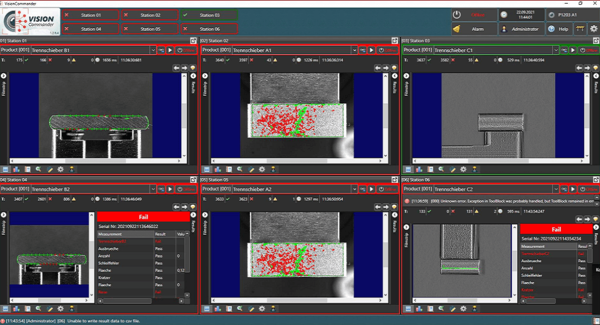

Realize reliable automated inspection in production with the VisionUnit. And benefit from powerful live evaluation.

The optical inspection unit is ideal for use between individual production steps and for end-of-line systems. Both one and several inspection steps can be carried out with just one VisionUnit. For example, the VisionUnit can be integrated alternately with several assembly steps and automatically check and record the success between each assembly step. The measurement results can be transferred to common MES systems. Configurable displays visualize the test results live on the system and supplement the vision system HMI on the control cabinet.

Instead of integrating individual components into a system, the VisionUnit offers the entire inspection technology in one module. This has clear advantages.

Quick installation in machines and systems is the top priority. The mechanical and electrical interfaces are standardized so that the VisionUnit can be integrated via plug-and-play. The testing technology is optimally set up before delivery. The housing protects sensitive components from dust and scratches. Moving cables can be optimally routed in the planned installation space of the VisionUnit so that they are characterized by a long service life. The compact design also gives machine and system manufacturers flexibility in the design of the system concept. Any conversion or retrofitting for a new application can be implemented quickly and easily.

Benefit from installation without previous experience, as the modular design allows easy configuration. Camera technology, lighting, mechatronics and software are perfectly coordinated.

The VisionUnit combines all of sensworks' expertise. Cameras, 3D scanners, various lighting technologies, projectors, sensors and mirrors - we are experts and know what every application needs. Defined mechanical and electrical interfaces. Focusing systems from modular axis systems and scanning applications can be perfectly coordinated if required. sensworks proven VisionCommander® image processing software, which evaluates and archives the data quickly and reliably, runs in the background. The result is high quality and reliability for automated inspection as a single package for our customers.

Mechanical & Plant Engineering

Mechanical & Plant Engineering

Fixed installation space

Process Lines in Manufacturing

In process or production lines, such as in the automotive industry, for example, one VisionUnit inspects the result between several production steps and can be used identically at several points.

Process Lines in Production

Standardized image processing

Rotary Indexing Machines

Rotary Indexing Machines

Many cameras in a small space

Quick and easy thanks to standardized electrical and mechanical interfaces. Optimum results thanks to integrated fine adjustment options for perfect alignment of cameras and lighting after installation.

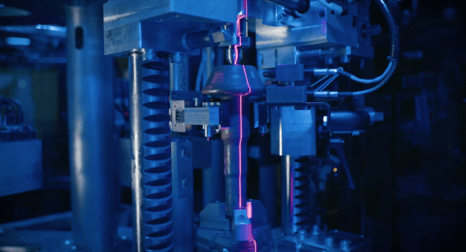

Proven axis technology creates flexibility in inspection - be it refocusing or the use of line scan cameras or 3D scanners.

We carry out the initial calibration of the cameras ex works, thus saving the time-consuming introduction of calibration agents into the machine.

Precautions for ambient light shielding protect against pseudo rejects and ensure reliable test conditions.

Connections for various communication modules enable a fast connection (e.g. individual HMIs, ProfiNet, Ethernet, ERP, MES and others).

Thanks to the modular design, flexible installation options are also available for retrofitting and upgrading.

Jochen Gollwitzer COO The VisionUnit is as compact as possible and as flexible as necessary to keep machine planning as simple as possible."

Clever functions for fast integration, short project planning and commissioning times and smooth operation.

Many interfaces have to be coordinated when a machine or production line is to go into operation. The VisionUnit inspection system offers a standardized solution that has been designed to be as compact as possible and as flexible as necessary to greatly simplify the commissioning of machines and systems.

.png?width=1580&height=963&name=Website%20Layout%2001(1).png)

The senswork optical 2D metrology system ensures the correct feeding of microchips in the semiconductor industry. Discover the benefits.

The image processing system from senswork inspects graphite surfaces in the automotive industry and reliably detects damage.

With our measuring system you can precisely measure the gap dimension of the contact surfaces of connector assemblies.

Rainer Obergrussberger

CEO

Business Development

senswork GmbH

Gewerbepark Lindach D 3

84489 Burghausen

Contact us!