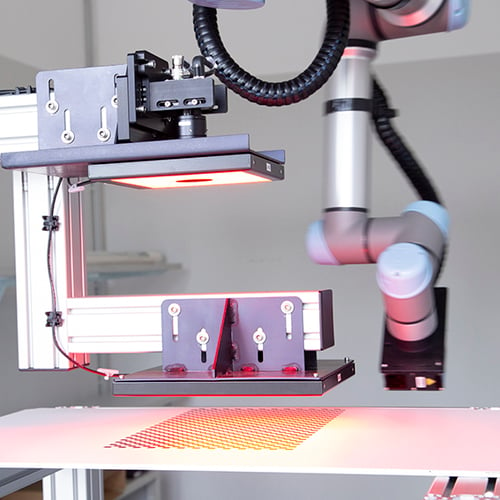

Our camera system uses position detection and completeness checks to ensure that trays are filled by a robot.

Robotic Vision

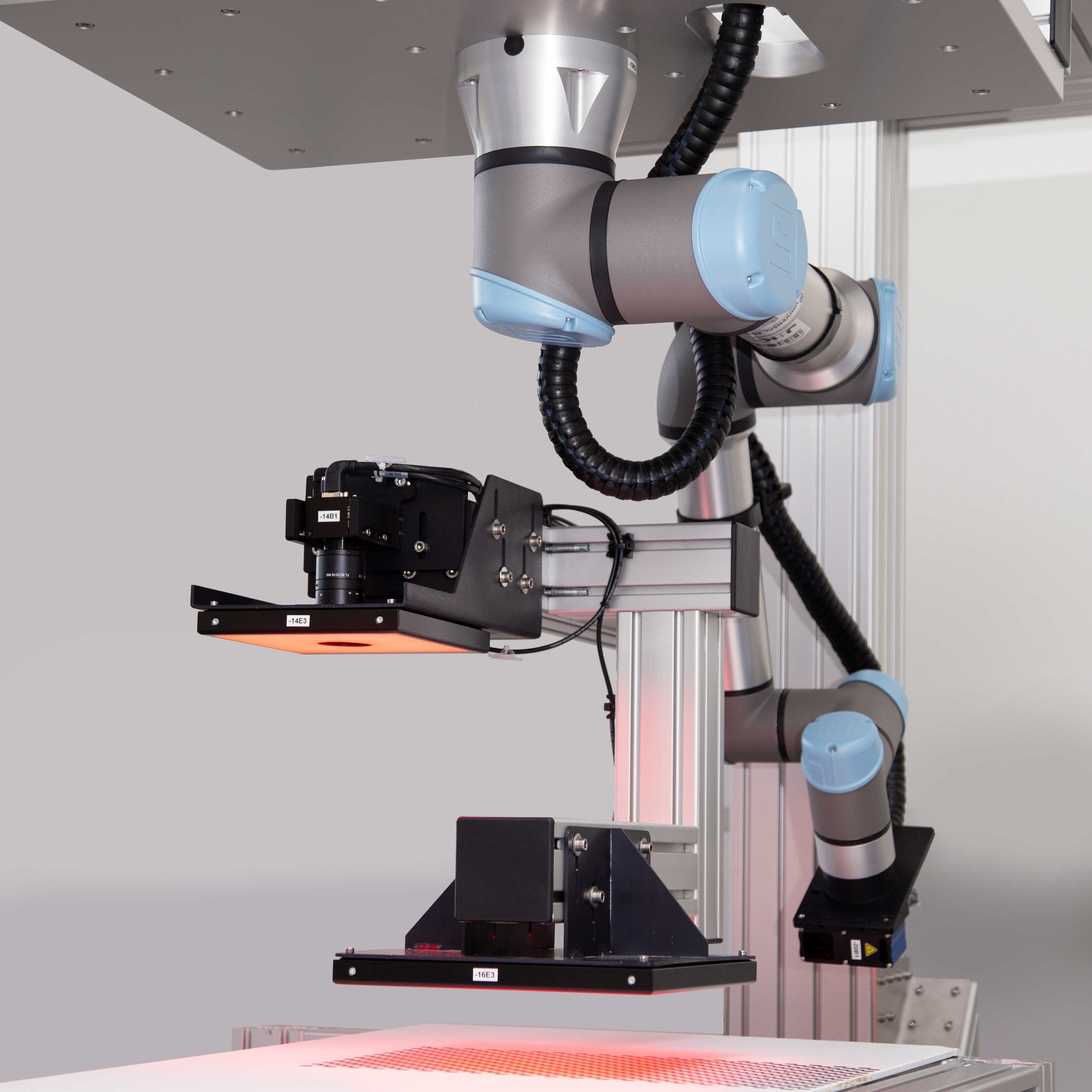

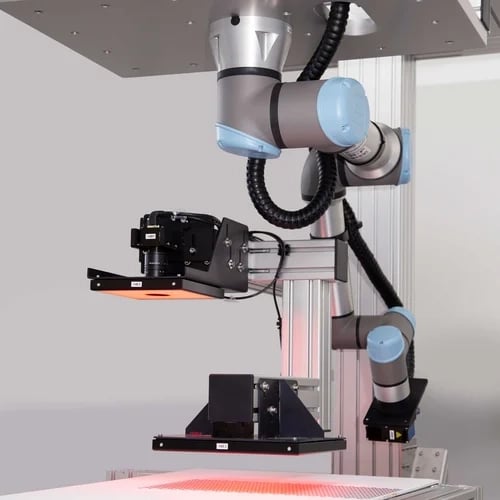

Robot with integrated image processing

senswork's Robotic Vision System (RVS)

Robot vision systems are an important component of automation technology and test automation

What is Robotic Vision?

Robotics + image processing for flexible automation

Robotic Vision is a technology that enables a robot to "see". Robotic vision systems combine the flexibility of a robot with powerful camera sensor technology and image processing software. Since the camera system is directly related to the gripper, this enables precise gripping operations as well as, for example, the localization of attachments to a product. The flexibility of 6-axis robots with focusable cameras and variable illumination methods in particular creates maximum flexibility in the inspection of parts.

Possible Applications in Industrial Manufacturing

2D and 3D cameras as end effectors on the robot enable a wide range of inspection options:

- End of line inspection of automated manufactured products

- Completeness check / presence of attachments

- 3D profile section measurement for measuring gap & flushness

- 360° 3D measurement of components

- 2D measurement over large fields of view

- Palletizing / depalletizing

- Combined inspections such as label inspection, fixture inspection, form and position determination

Robotic Vision from senswork in Action

Benefits

For different part variants and in particular part sizes, a robot provides the necessary flexibility to move the camera sensors to the right position. Linear motion sequences are also possible, for example to scan large-area parts in 3D. Different working distances and field of view sizes are realized with electronically focusable optics.

Instead of many static sensors or cameras, only one flexible camera unit is needed on the robot. This can greatly reduce project costs. Advantage with senswork: With our expertise, we develop precisely fitting VisionUnits for the end effector, and also integrate the robot - so you get everything from a single source.

Only complete automated inspection after production creates the certainty of 100% defect-free products. Robotic Vision helps to further automate and perfect previous visual or manual inspections.

2D & 3D Robotic Vision Technology

At senswork, we integrate state-of-the-art 2D and 3D camera technology in conjunction with robotic systems - turnkey, indvidual and all from a single source.

2D Robotic Vision by sensork

- 2D measurement of parts in different focus positions

- Variable illumination setups / flexibly switchable

- Calibrated systems: measurement of large parts by multiple image acquisition and image stitching

- All optical components fully integrated as vision unit at the end effector of the robot.

- Combinable with AI! The complete toolbox of senswork from 2D tools to AI tools is also available in the robotics vision area.

- The complete sequence control is done by our image processing framework VisionCommander©.

3D Robotic Vision

The combination with 3D cameras and laser scanners in particular creates a wide range of possibilities in the optical inspection and measurement of parts:

- 360° 3D scanning of parts, offline and inline

- 3D metrology with robots: presentation of parts or 3D sensors in different perspectives for complete capture, measurement and comparison against CAD

- Determination of presence or correct assembly position of parts through 3D data

- Profile section measurement through the integration of 3D profile scanners (laser scanners)

- 3D measurement of shape, distance, angle, flatness

- 3D surface inspection

Robotic vision solutions

Automated 3D inspection of cylindrical cell modules for flawless battery production: precision and efficiency directly in production.

Efficient robot-assisted 3D inspection from senswork for error-free production, immediate error detection, and precise 3D measurements directly on the production line.

Rainer Obergrussberger

CEO

Business Development

senswork GmbH

Gewerbepark Lindach D 3

84489 Burghausen

Getting Curious?

Contact us. You can call or leave a message: