Quality of transparent material

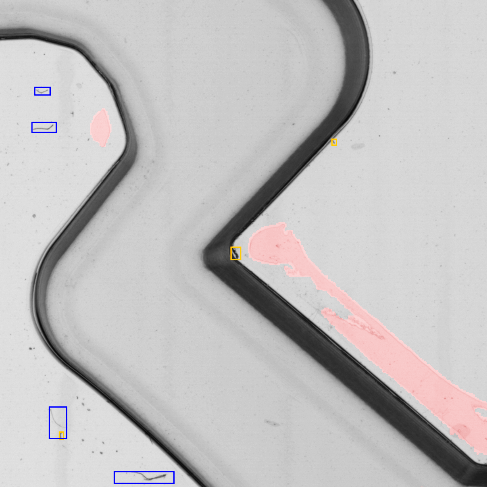

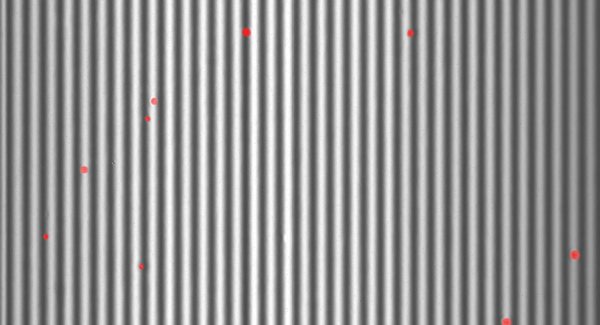

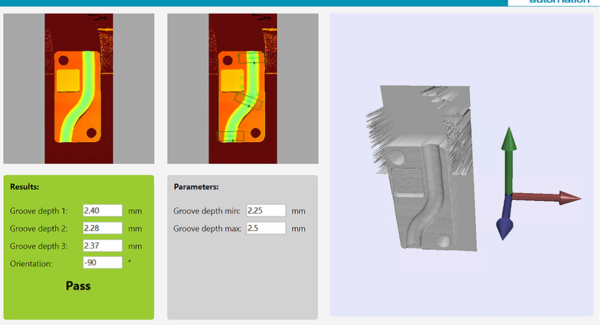

PackagingVisual inspection systems verify the quality of transparent plastic packaging such as film or bottles. This includes surface inspection, leak testing, and reading and verifying fonts and codes. Even warped or reflective surfaces do not present a challenge for our camera systems.