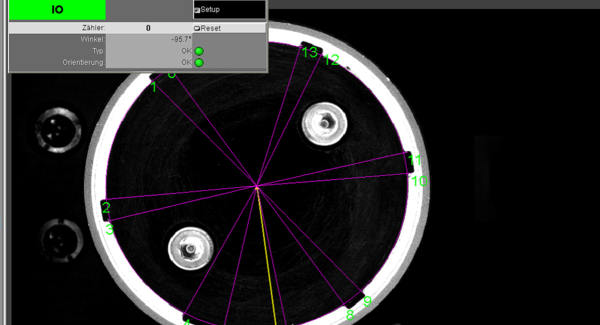

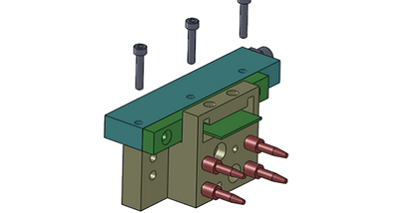

Learn how an optical measuring system from senswork ensures the precise assembly of circuit elements for electric stoves.

Complete turnkey systems for automated 2D measurement and inspection

Quickly and precisely check geometric parameters of parts in one level? That's possible with senswork's optical 2D measurement technology.

Solution for fast, automated measurement

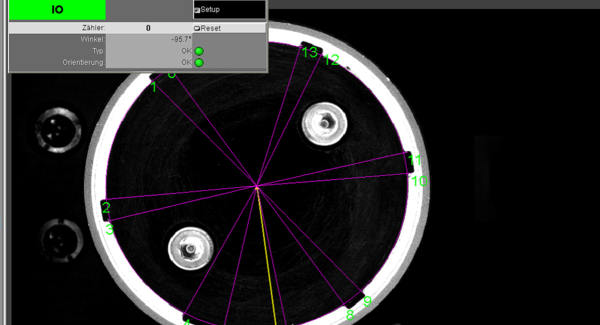

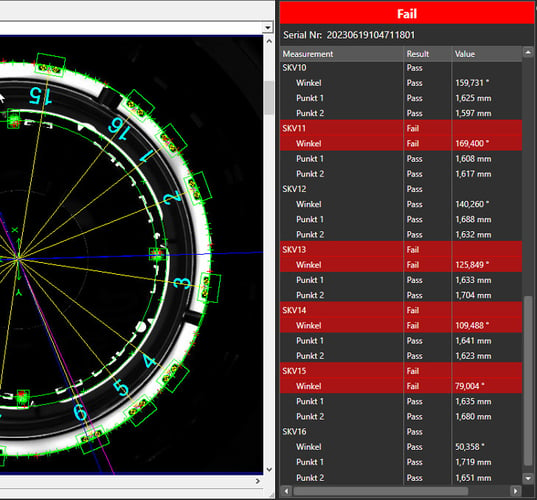

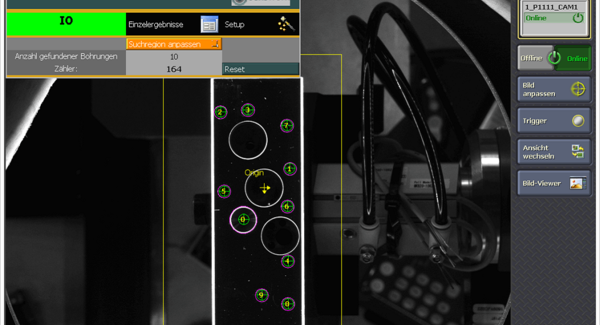

Optical 2D metrology determines dimensions and checks geometric deviations while taking into account references and tolerances. Typical tasks include the inspection of contours, radii, distances, positions and angles, or the detection of defects such as interfering contours, missing holes and breakouts. The focus here is on proving the measurement capability of an optical system according to standardized specifications.

We take care of the selection

We have many years of experience in industrial image processing. That's why we can precisely define the hardware and software requirements and correctly assess the measurement and inspection tasks from the very beginning.

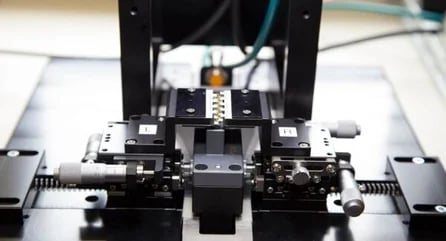

Our camera-based measurement systems for gap or position inspection are designed according to standardized measurement standards to ensure measurement capability in the factory. Certified calibration standards allow validation of camera calibration specifically for measurement tasks.

We guide you from the feasibility study to the commissioning and acceptance of the systems. All from a single source.

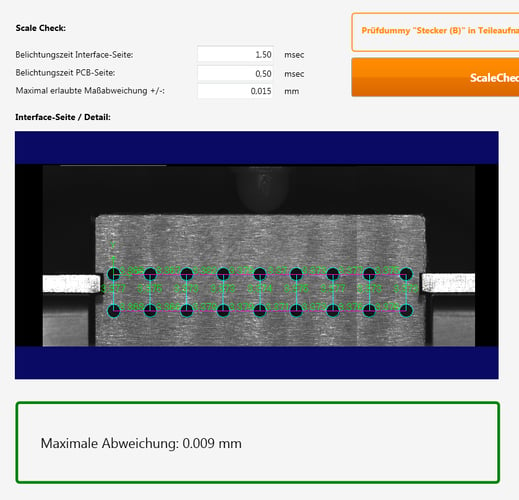

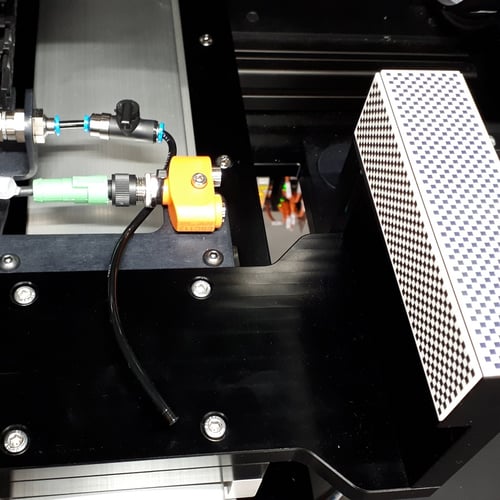

Calibration of camera systems plays a critical role in ensuring accurate and reliable measurements of optical systems. We use calibration tools such as checkerboard or dot patterns to optimize the calibration process.

At senswork, we manufacture and integrate precisely fitting calibration means that can also be used in the machine context. This allows recalibration in the production line without having to remove the camera.

Upon request, we can have calibration standards measured by DAKKS-certified institutes to best meet our customers' QA requirements.

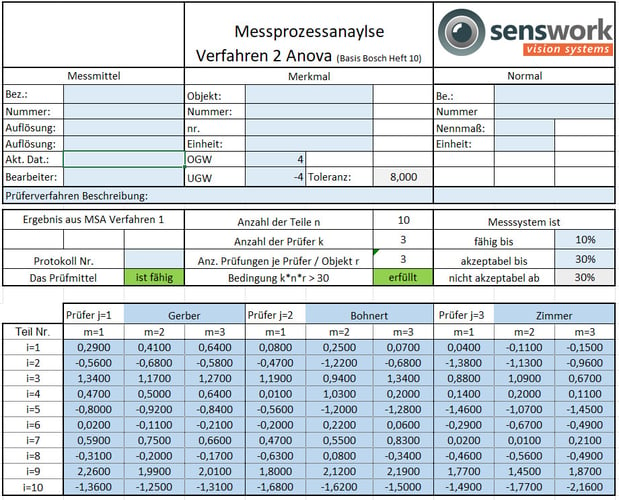

The selection of the appropriate MSA standard depends on the respective industry and the specific requirements. In many cases, several standards are combined to perform MSA according to individual needs. The correct application of these standards is crucial to ensure accurate and reliable measurements and to improve the quality of products and processes.

We work with you to perform MSAs (Measurement System Analyses) during the validation of our optical measurement systems. If required, we can also provide the appropriate calculation tools.

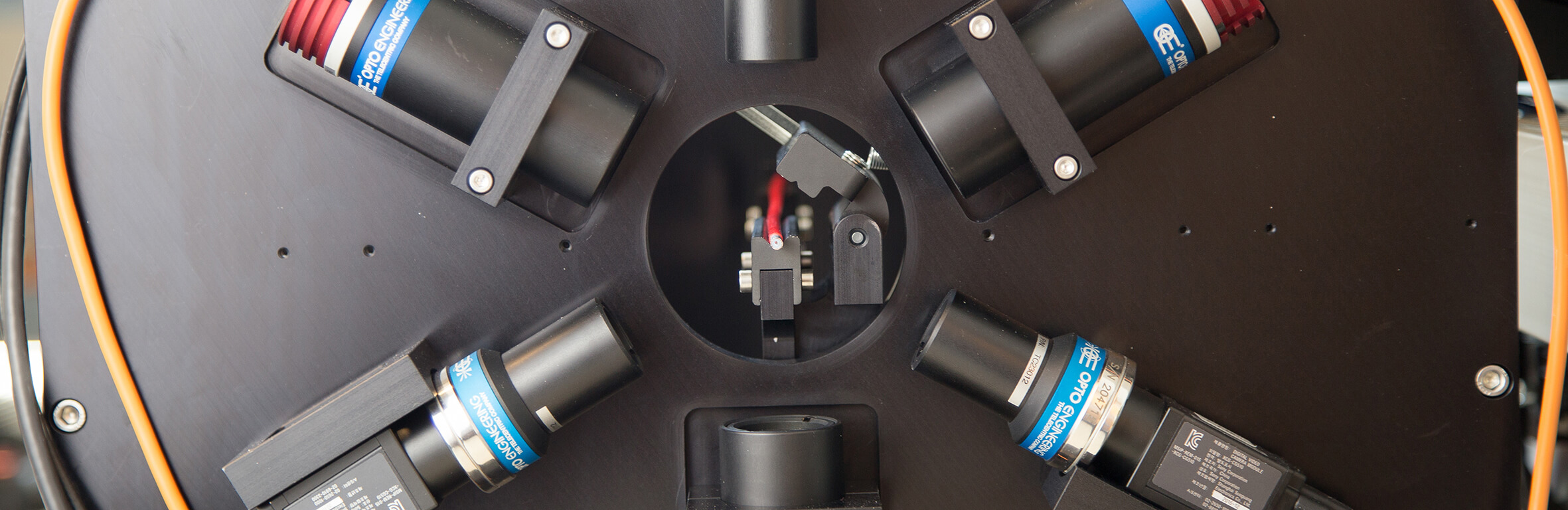

We specialize in designing optical measuring and testing systems with more than 25 years of experience. As a manufacturer-independent provider, we always select the most suitable hardware to also ensure maximum accuracy and availability later for ongoing operation.

As a provider of turnkey inspection modules and measuring and testing equipment, we take all inspection-related issues into our own hands and ensure smooth project execution and the best possible risk avoidance from the very beginning.

Our multidisciplinary team consisting of experts in optical measurement and inspection technology, mechanical and electrical engineering as well as our software team develops unique camera solutions to perfection on a daily basis.

Learn how an optical measuring system from senswork ensures the precise assembly of circuit elements for electric stoves.

Capture the position and location of welding spoons with transmitted light illumination from senswork. Reliable and precise.

Learn how senswork's optical measurement system automatically detects different sized holes on airbag assemblies.

Andreas König

Director

Sales

senswork GmbH

Gewerbepark Lindach D 3

84489 Burghausen

Contact us!