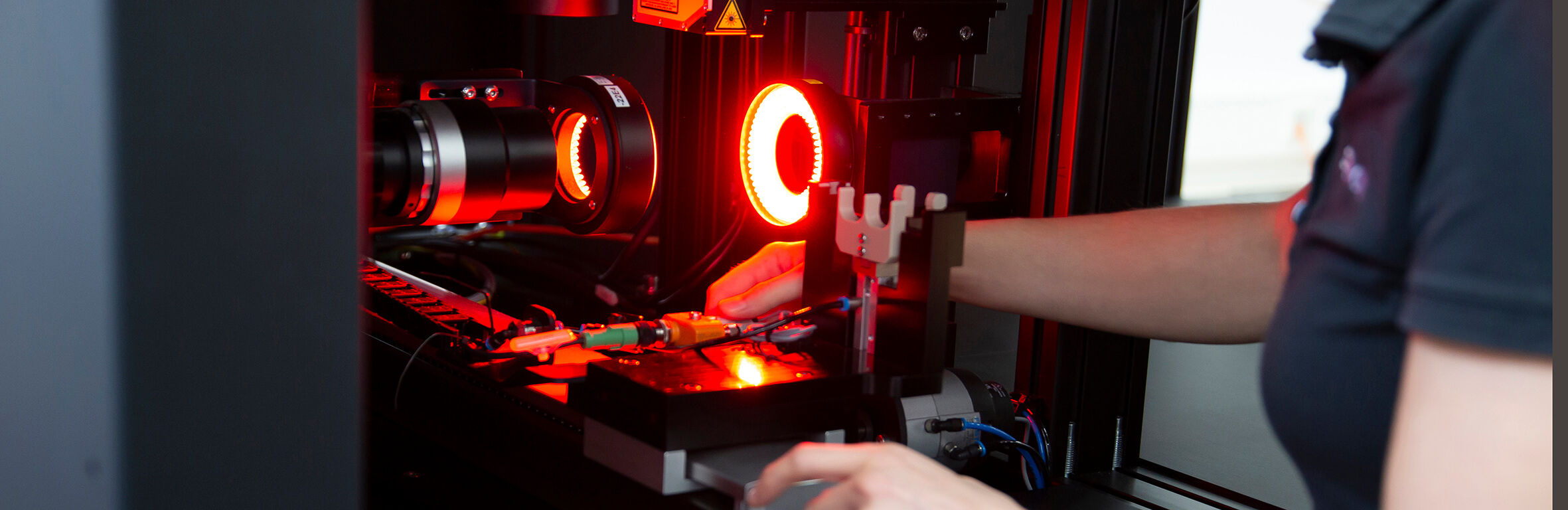

With its testing station, senswork ensures the quality of transparent cartridges for medical technology. Directly in the production process.

Universal Machine Vision Software for 2D, 3D and Deep Learning

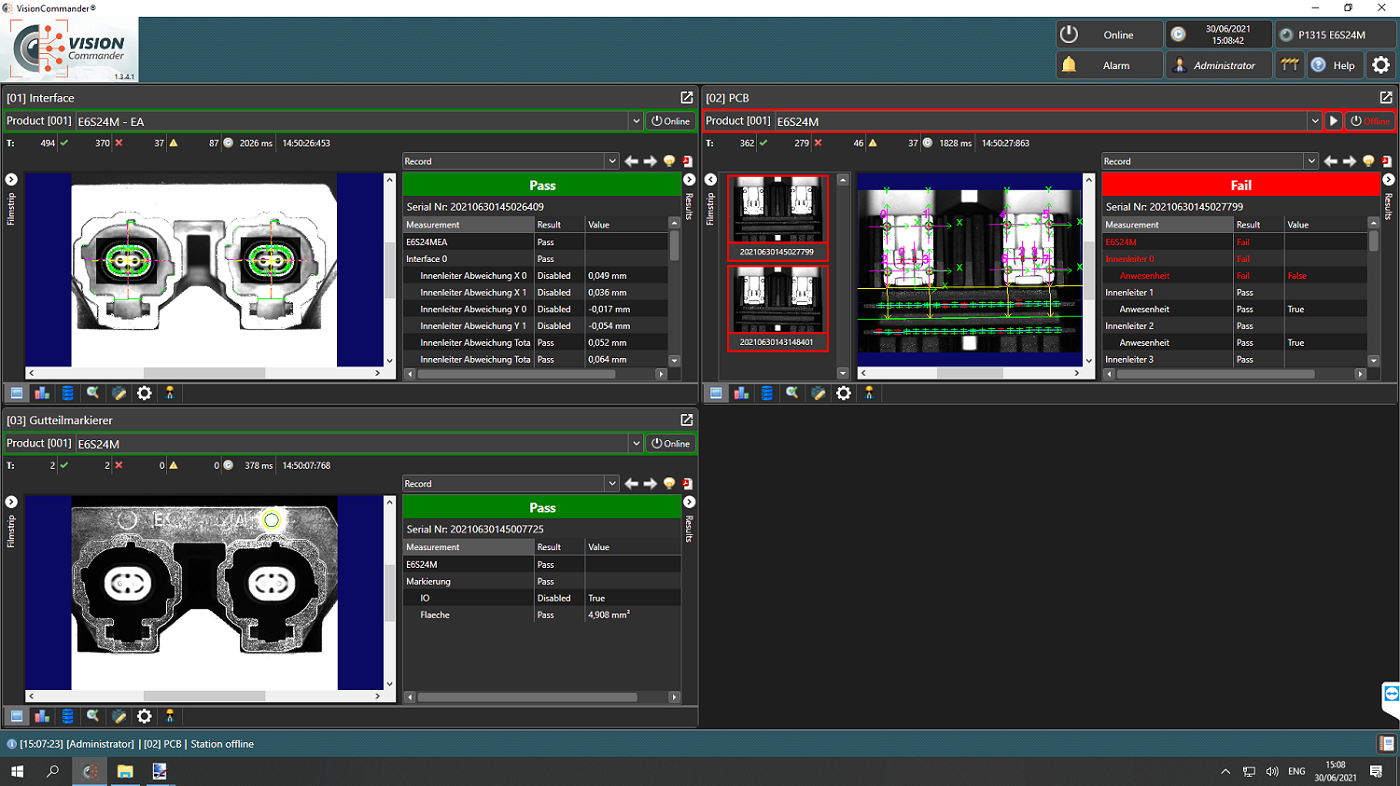

VisionCommander® scores with high performance for efficient inspection processes and with an intuitive user interface

.png?width=700&height=500&name=Bild11%20(2).png)

High performance for automated inline production

Our PC-based image processing software is used daily by numerous customers in industry. In automatic inline inspection, it ensures the highest standards of reliability, performance and intuitive usability.

VisionCommander® offers 2D as well as 3D measurement and inspection tasks, and includes powerful Deep Learning features.

The software can perform up to eight inspections in parallel in separate windows, offering a major cost advantage over smart cameras, especially for large installations.

VisionCommander® supports 2D and 3D cameras and scanners from different manufacturers. So you always get the best system configuration without compromise

2D Metrology

Determine exact dimensions

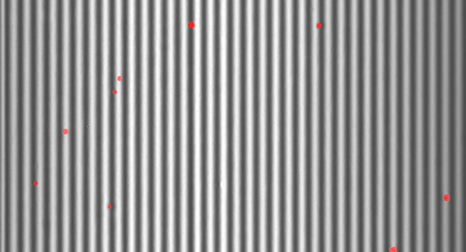

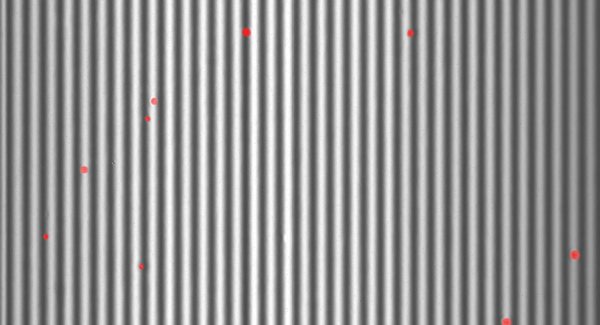

Surface Inspection

Guarantee perfect surfaces

Deep Learning

Solve complicated inspection tasks efficiently

3D Metrology

Precisely measure structures

Label Inspection

Recognize fonts, codes and symbols

3D Inspection

Capture shape and position of products

User Interface

In VisionCommander®, up to eight inspection stations are possible using a maximum of 8 cameras simultaneously. The individual stations are clearly displayed in separate windows including all relevant result values, image strips and image overlays. Result data can optionally be visualized numerically and graphically with target values. This gives you a quick overview of the status of the inspections currently in progress.

Deep Learning Features

VisionCommander® supports two well-known Deep Learning tools:

VisionCommander® combines classical image processing with Deep Learning functions such as classification, semantic segmentation and object search. Our Deep Learning tools work not only with 2D but also with 3D data, making them unique in the world of machine vision!

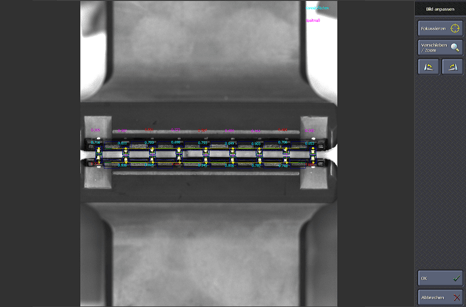

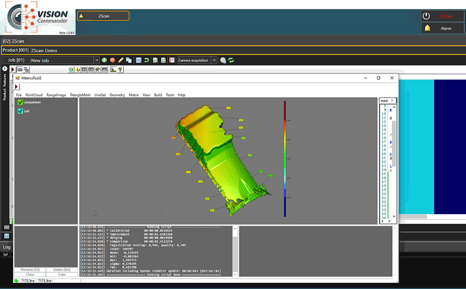

senswork 3D Metrology Framework for Fast Processing of 3D Point Clouds

3D features include:

Scanning with Multiple Sensors

VisionCommander® 3D calibration enables the merging of multiple 3D scanners into one point cloud coordinate system.

Statistics Module

Digital Reference Part Check

Digital reference part check verifies inspection tasks against a defined set of sample images and enables PDF reports on the results. This ensures that the current inspection tasks, including the set parameters, are working correctly.

Comprehensive 2D Tools Based on Cognex VPro

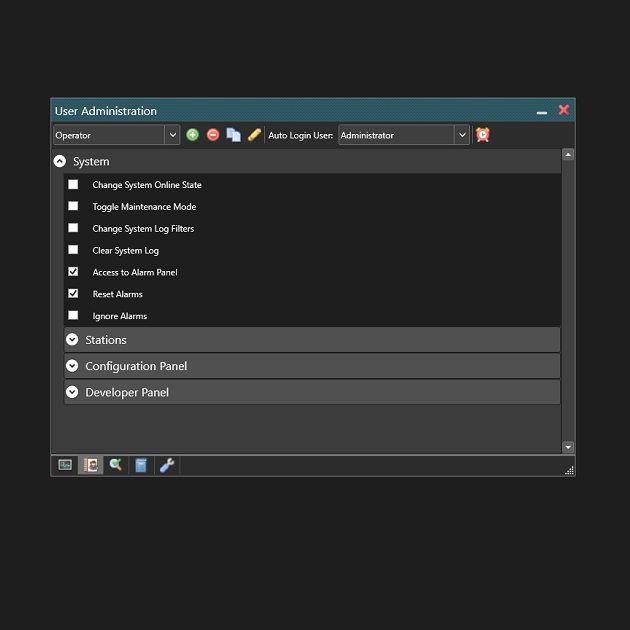

Flexible User Administration

VisionCommander® offers flexible user administration, role assignment and definition of permissions. A user can be defined with free assignment of rights. This protects against unauthorized changes to inspection-relevant parameters during ongoing production.

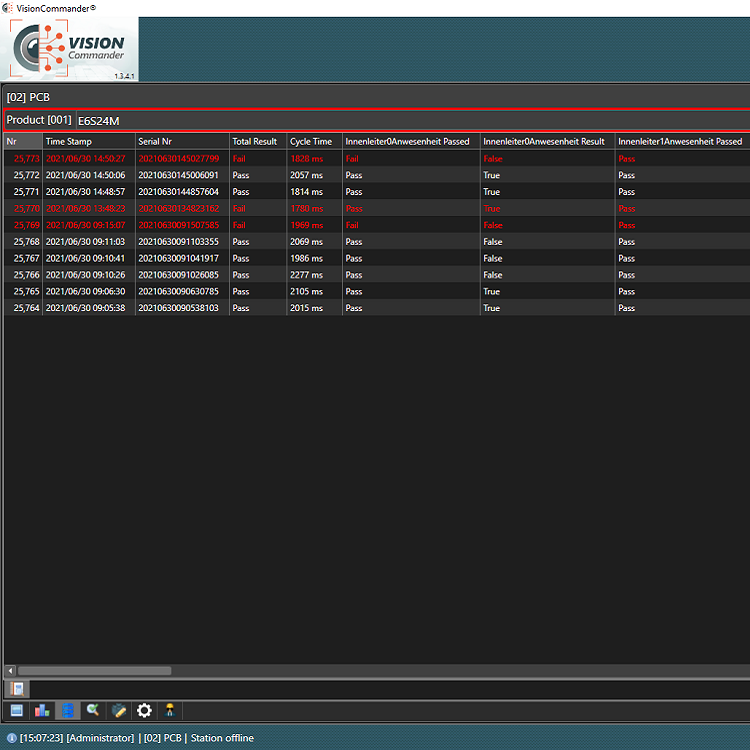

Relational Database for Storing Data from Results

Flexible Product Management

VisionCommander® saves parameters and result data product-related. This gives you the best possible overview in production.

Options:

VisionCommander® Audit Trail

VC Audit Trail tracks all parameter changes during operation, and stores them in a database along with the ID of the logged-in user, timestamp, and the change made.

VisionCommander® Data Analyzer for Rework Stations

Offline software for visualizing inspection results on rework stations.Connectivity

VisionCommander® works with many common interfaces, including:

VisionCommander® supports 2D and 3D cameras and scanners from a wide range of manufacturers. The software can run up to eight inspections in parallel in separate windows. At its core, it has various calibration mechanisms for demanding measurement tasks.

The results of the inspection are stored in real time in an SQL database. The database enables detailed analyses and data tracing in production. A flexible statistics module also provides a quick overview of the current quality status in production.

Various additional tools such as film strips, logging on multiple levels and the import and export of jobs make VisionCommander® a powerful tool that is compatible with common interfaces such as GigE Vision, USB, GenICam, Camera Link, CoaXPress as well as the PLC interfaces Profinet and ADS.

With the so-called Part-Template-Builder, an image of test parts with measurement characteristics can be created. This image is automatically included in the statistics and database module. The flexible user administration allows easy handling of user roles.

With its testing station, senswork ensures the quality of transparent cartridges for medical technology. Directly in the production process.

senswork's 3D inspection camera system improves the quality of gear shafts in harsh environments.

Learn how AI-based image processing from senswork detects bubbles, inclusions and defects in transparent sheets.

Product Guide

Rainer Obergrussberger

CEO

Business Development

senswork GmbH

Gewerbepark Lindach D 3

84489 Burghausen

Contact us!