Deep Learning can be used to reliably read expiration dates on yogurt containers. AI enables reliable inspection.

Check codes and fonts quickly and reliably

OCR, OCV testing, and label inspection for the automotive, food, medical technology, and electronics industries

With senswork OCR & OCV character recognition for industrial applications, you can ensure that every print and every label in your production is error-free. Whether it's a best-before date, serial number, batch code, or barcode, our OCR solution ensures that everything is read and checked quickly and reliably. With many years of experience and thanks to our innovative senswork AI technology, we also solve challenging applications with curved, rough, or reflective surfaces with flying colors.

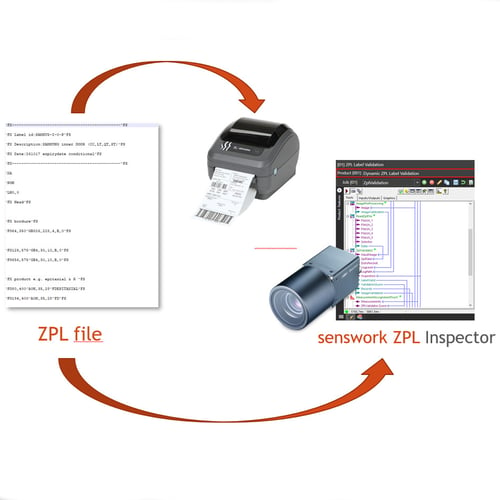

We complement our offering with the senswork ZPL Inspector, which generates and executes its inspection program fully automatically based on ZPL printer files.

Mit automatisierter Code- und Schrifterkennung von senswork verbessern Sie:

Verified character quality, completeness, and greater control

With faster throughput rates and automated inline inspection

Through 100% inspection of the imprints or embossing at the factory

Thanks to scalability, multilingualism, and integration into existing systems

Reduces waste, personnel costs, and protects against product recalls

From standard to special cases: With senswork, you can implement reliable and powerful OCR inspection. Tailored to your application. With or without AI.

Make processes more efficient through customized further processing and documentation

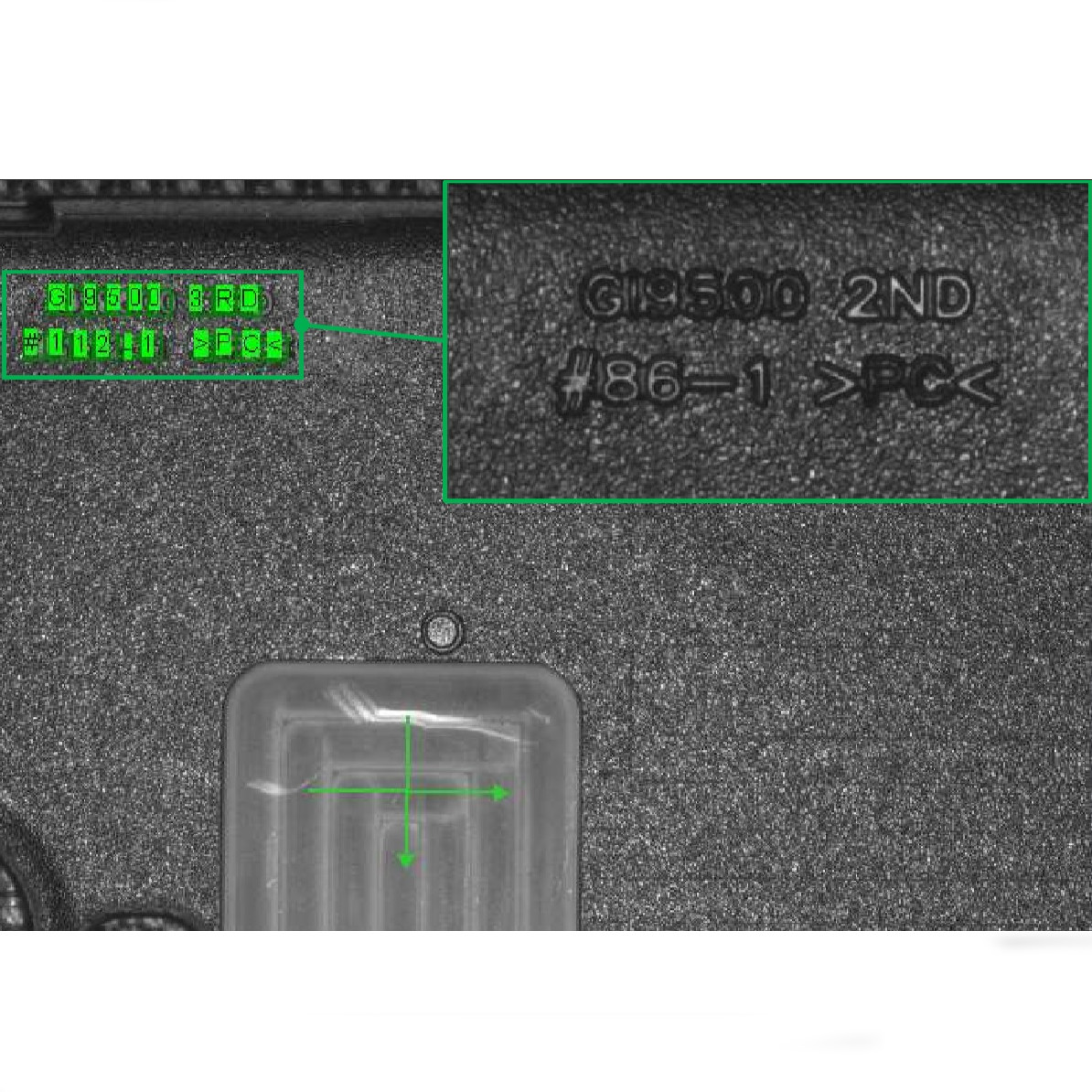

With senswork's automated OCR character recognition, different component variants can be identified directly in production and reliably categorized, sorted, and further processed based on their codes. This allows manufacturing processes to be individually controlled and made more efficient, as component types can be identified quickly and without errors.

The products can be automatically stored and statistically evaluated at all stations. This allows for the establishment of complete production and supply chain documentation.

One example application is the reading of codes on tires using our AI-based OCR system, the senswork Tire Code Reader. > Learn more about the senswork Tire Code Reader

Fully automatic recording and checking of character quality, completeness, position, and accuracy

OCR systems from senswork reliably recognize and check:

Easy to integrate, scale, and internationalize

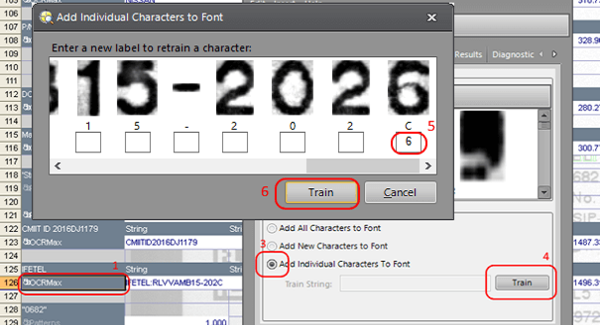

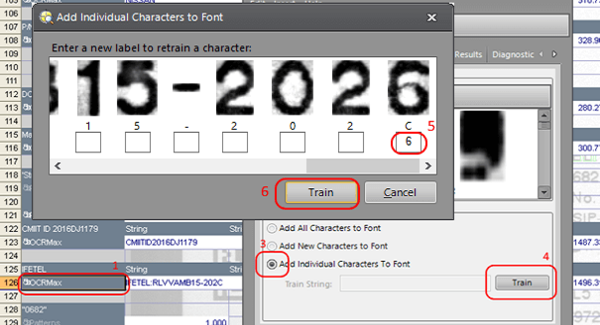

Industrial solutions require reliability. Position yourself flexibly and future-proof: senswork OCR systems can be easily integrated into your existing systems. Our solutions are flexible and adapted to your situation. At the same time, scaling to additional systems or changes to the inspection request, e.g., additional characters to be inspected, can be implemented at any time.

Reading and checking different languages and characters, e.g., Asian or Cyrillic, is also possible with OCR systems from senswork.

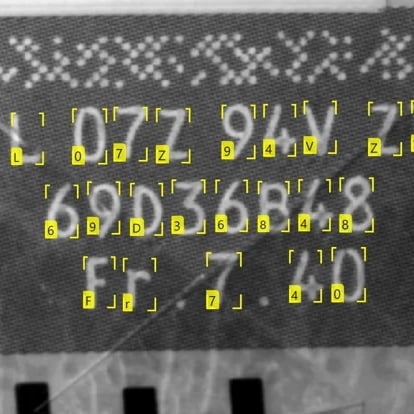

The AI method of deep learning demonstrates its strengths in OCR applications precisely where traditional image processing tools reach their limits. Our sophisticated AI-based OCR systems solve challenging use cases:

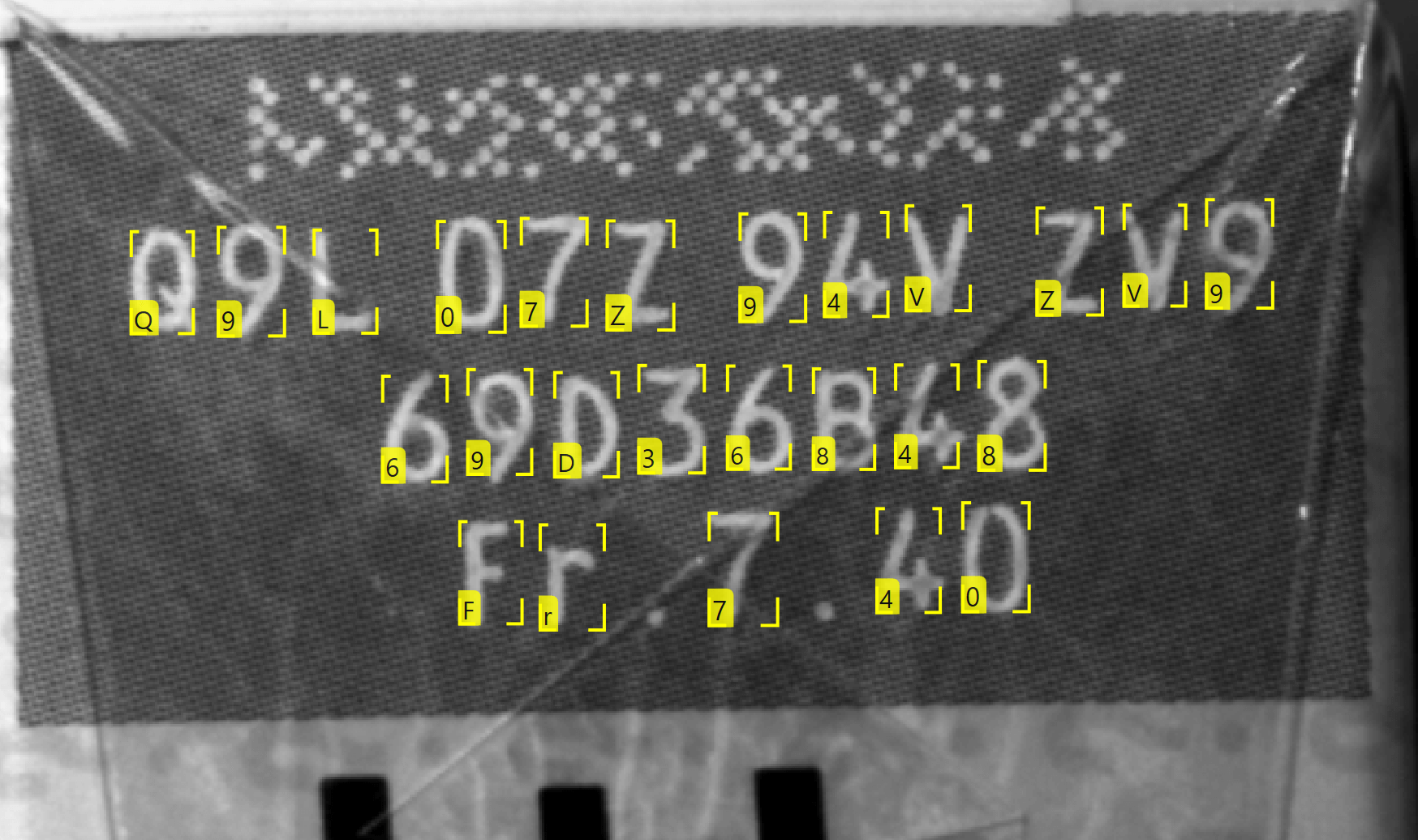

The segmentation process was a major challenge for previous OCR systems. Fluctuating brightness or variable backgrounds could quickly lead to incorrect readings. senswork's AI-based OCR solutions, on the other hand, are able to segment and classify characters even on non-uniform backgrounds. For example, on thin plastic packaging in the food and pharmaceutical industries. This significantly increases reliability and robustness in many industries.

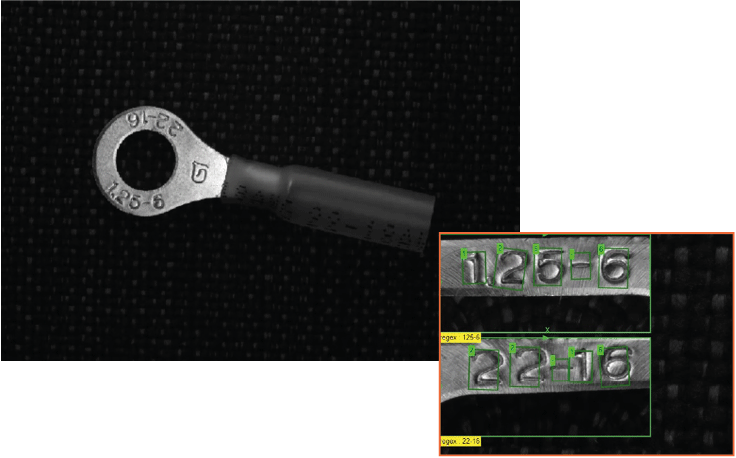

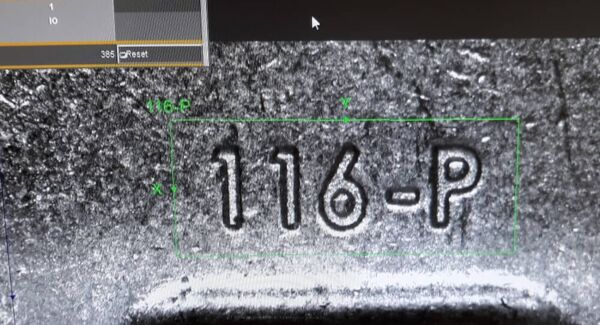

Similar to inhomogeneous backgrounds, weak contrast can quickly overwhelm traditional character recognition systems. Here, too, the senswork OCR solution with deep learning demonstrates its strengths. The AI-based OCR system reads even raised lettering on rough surfaces such as cast aluminum or tires robustly and reliably.

AI-based OCR systems from senswork are characterized by their adaptability and can easily handle different fonts, font sizes, and layouts without requiring time-consuming manual adjustments. Especially with stamped or embossed fonts and inkjet printing (for example, best-before dates on food packaging), the character representation can vary considerably, even though the text remains legible to the human eye. This is where our AI-based OCR solution shows its strengths.

Thanks to its training, senswork's AI-based OCR solution has a diverse collection of fonts at its disposal, enabling it to effortlessly handle a wide range of characters regardless of their size, style, or stroke thickness without prior training. If necessary, additional characters can be integrated into the training to further increase the robustness of the system.

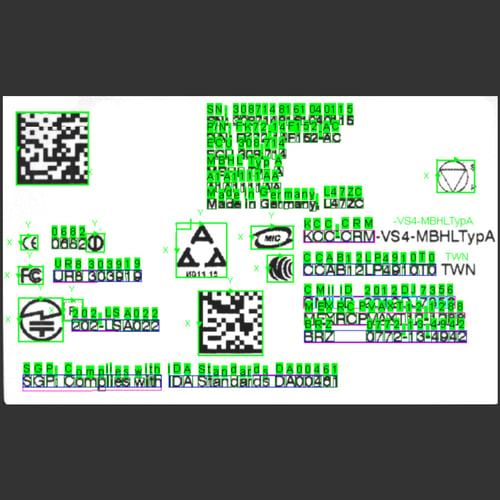

Read directly marked and printed codes and evaluate quality

OCR systems from senswork enable the identification and traceability of products and components using barcodes in accordance with standards such as AIM/DPM or ISO/IEC 15415. This allows the quality of directly marked barcodes as well as printed 2D codes to be evaluated. Various methods used to apply barcodes, such as laser marking, dot peening, or printing, can be reliably captured, documented, and evaluated using senswork's code and character recognition technology.

Yes, thanks to senswork's ZPL Inspector

The ZPL Inspector from senswork enables direct interpretation of ZPL (Zebra Printer Language) print jobs and automatic generation of inspection programs. This means that our ZPL Inspector camera solution adapts fully automatically to the print layout without the need to change the inspection program. The contents of the ZPL printer file are read and interpreted, and a corresponding inspection program is generated from this – fully automatically and without user input.

The following print elements can be read and interpreted automatically:

Example applications of OCR code and character recognition from senswork

Ensure that symbols, codes, and markings on vehicle parts or tires are complete, legible, and contain the correct information. Identify product parts and process them automatically.

Check the printing on food packaging to ensure that it contains the correct information about ingredients, nutritional values, and allergens, and that the best-before date is printed correctly.

Easier compliance with legal requirements thanks to documented product history at component level. Clear identification of each product component. Simplified automated further processing.

Automatically check text on electronic products: correct information about safety warnings, batch numbers, etc.

We have extensive experience in planning and implementing OCR solutions for industrial applications. Together with our customers, we develop efficient and reliable systems based on our expertise in image processing and our own AI research. After all, optimal results can only be achieved through the right combination of technology, resolution, lighting, and software.

Our offering includes a perfectly coordinated complete package of hardware and software: from camera resolution and lighting to the selection of suitable wavelengths – whether visible light or infrared. For complex OCR tasks on challenging backgrounds, we use our AI-based tool senwork Neuralyze©, as well as our image processing software VisionCommander®.

You can count on us—as an experienced partner, we will bring your OCR project to a successful conclusion efficiently.

Deep Learning can be used to reliably read expiration dates on yogurt containers. AI enables reliable inspection.

A dual camera system with mirror deflection enables OCR verification of part numbers on turbocharger guide vanes.

The smart camera from senswork enables reliable inspection of texts, codes and symbols - even at a great distance.

Andreas Koenig

Head of Sales

Sales

senswork GmbH

Gewerbepark Lindach D 3

84489 Burghausen

Get in touch with us! Give us a call or leave a message.