Quality assurance of transparent cartridges with AI

Application and Solution

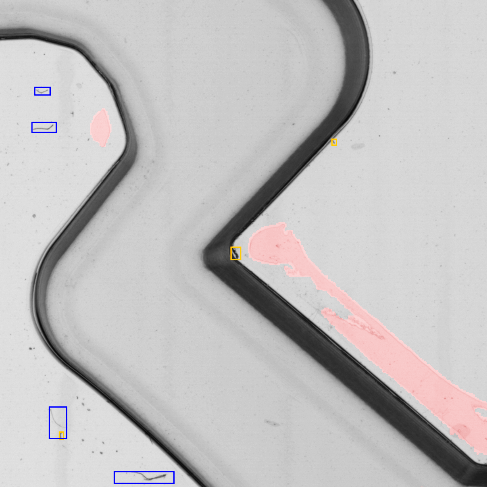

High-precision, transparent polymer cartridges can be detected in the production cycle with senswork's inspection station and reliably evaluated using AI software. This technology enables 100 % quality assurance of LabDisks or Lab-on-a-Chip designs in the production cycle.

Inspection with the aid of the AI inspection station takes place inline during production at the manufacturer. A high-speed digital microscope captures the 150 mm wide transparent LabDisks with a resolution of 10 micrometers. The AI software Neuralyze® detects and distinguishes liquids, delaminations and the position of particles and dust on this image data. At the same time, the process time is 80 % less than the cycle time of the preceding sealing process. With this high speed, LabDisks can be inspected for quality directly in the production process.

The detection and evaluation of transparent surfaces with the smallest qualitative deviations was previously considered a major challenge. With senswork's innovative technology, coping with such inspection situations becomes state of the art.

Learn more about Neuralyze® image processing software.

Tasks

- Independent quality inspection of LabDisks in production

- Detection of transparent structures in the µm range

- Detection of delaminations in the µm range

- Detection of particle positions in the µm range

- Differentiation of liquids

- Qualitative evaluation via AI

Benefits