Quality Assurance for Industrial Automation

Machine Vision Systems from a One-Stop Shop

Our Passion

We develop custom-fit machine vision solutions for complex quality assurance tasks - efficient, precise, and innovative

Our Offer

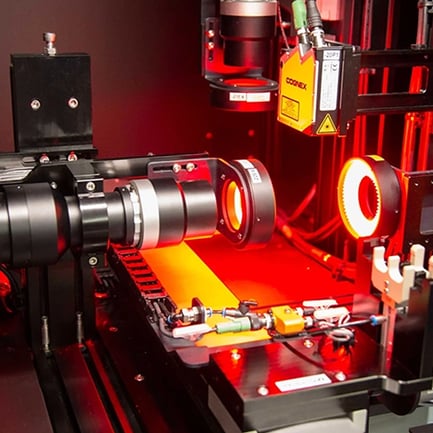

Optical Measuring & Testing Technology

Sophisticated Methods

Optical Measuring & Testing Technology

Sophisticated Methods

Solutions

Successful Applications

Solutions

Successful Applications

Products

Vision Software & Hardware

Products

Vision Software & Hardware

State-of-the-art image processing: senswork AI in optical inspection

3D acquisition of shape, position & surface

To ensure flawless surfaces

Final product inspection

Pick & Place for robotic systems

Optical 3D Inline Measurement Replaces CMM

Testing of printed or embossed symbols, text, codes on a wide variety of surfaces

Measure, inspect and avoid errors in 2D

The Right Technology

At the beginning of a project, we select the right measurement and inspection technology for your specific application. Based on this, we develop your customized vision system. Our solutions automate measurement and inspection processes, resulting in a fast return on investment. They also save you time, resources and space. In addition, our technologies help reduce scrap in manufacturing processes. We place great emphasis on high precision, reliability and the optimization of your processes.

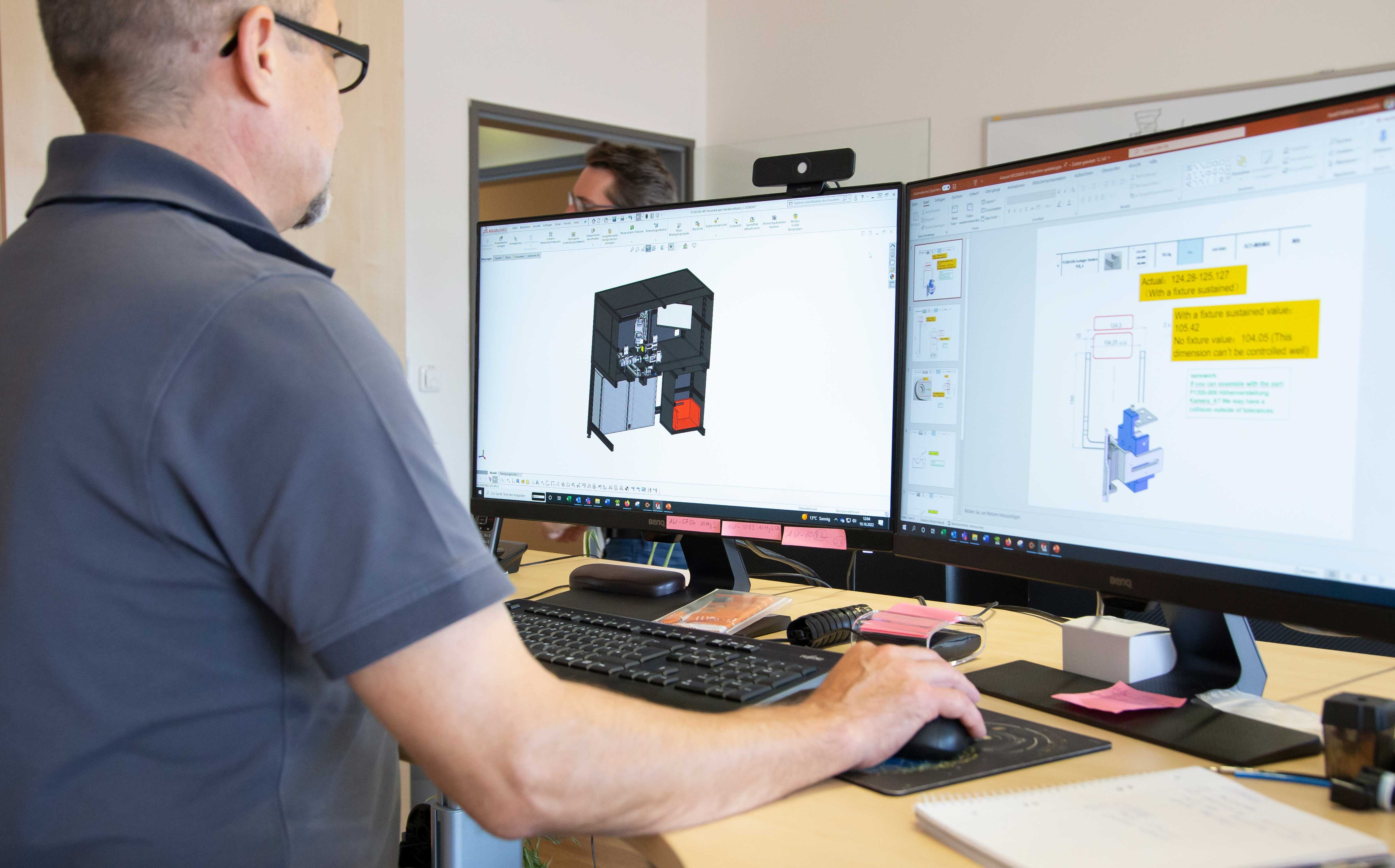

All designs of our measuring and testing systems are created in the design department. Precisely tailored to your requirements.

Our software architects are constantly developing the software applications, so that your products are reliably tested.

Our turnkey measuring and testing systems are created in our workshop. They also undergo tests here before they are delivered.

Our support team accompanies you throughout the entire project until commissioning. Even after completion of a project, we are there for you.

Our Expertise

From initial concept to commissioning - our multidisciplinary team manufactures machine vision systems in-house

References

-

Wolfgang Gmach Siltronic AG We value senswork as a reliable partner when it comes to camera-based solutions. We use the systems, which were developed specifically for us with a high level of customer orientation, at all of our production sites globally."

senswork Innovation Lab

In the Munich Innovation Lab, we develop new approaches to solutions with AI

We capture new findings and technologies for industrial image processing at an early stage in order to make them usable in industry and research. In the senswork Innovation Lab, we dedicate ourselves specifically to AI technology Deep Learning, which offers new possibilities for demanding inspection tasks in image data analysis and thus in automated production processes. In this way, we are paving the way for the future of quality assurance in the machine vision industry.

Do you need a solution for automated optical measurement or inspection? Don't hesitate to contact us. Send us a short description of your inspection task, the manufacturing environment and information about the object. Our team of experts will be happy to assist you!

Highlights

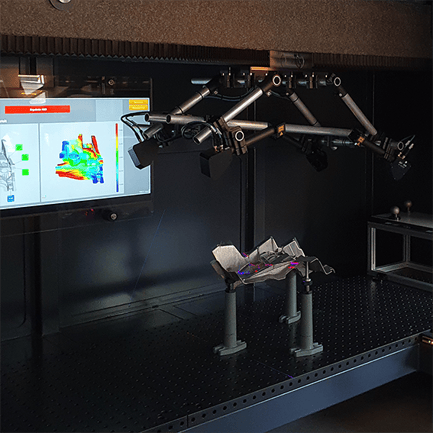

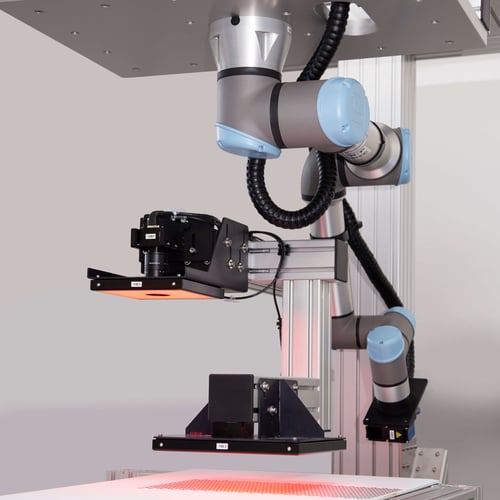

Camera guided robotics

senswork & Robotic Vision

Robots are a useful helper - not only for gripping components, but also for aligning cameras or 3D sensors to different inspection areas of a component. We offer optical measurement and inspection systems in combination with collaborative robots.

Optimizing processes with AI

senswork Neuralyze® Vision AI

Pasta products such as gnocchi and spaetzle are produced in a very similar way. When production is switched from one manufacturing process to another, it is important to ensure that the pasta is packaged according to type. Visual inspection using deep learning helps distinguish between them. Find out how AI technology is improving the process and the expertise behind it.

Company brochure

Learn more about senswork

Our company brochure provides a brief overview of our competencies, product portfolio and services in the field of machine vision.

.png?width=700&height=500&name=senswork-brochure-w(1).png)

We are committed to sustainable development and act responsibly because we believe in what we do. And we lead by example, treating our employees with respect and supporting their professional growth and development. It also goes without saying that we use resources wisely and that our products are safe and efficient.