Inspect washtrays for fractures and component freedom

Topics

Surface Inspection

Completeness Check

Industries

Automotive

Application and Solution

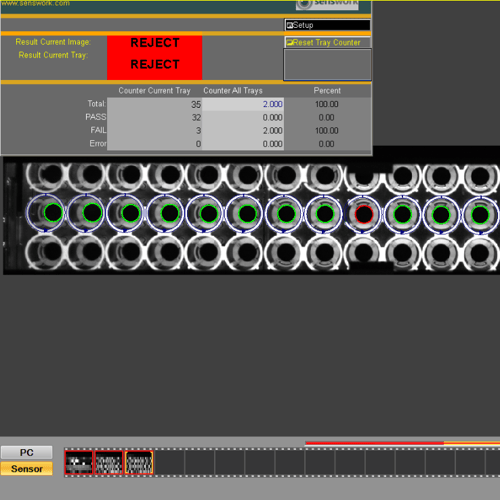

Enormous quantities of battery cases are produced daily in battery production for electric cars. Our camera system inspects the holders of the battery casings for possible damage, fractures and unremoved casings in order to secure the subsequent fully automatic reassembly.

Tasks

- Detect fractures and component freedom in washtrays

- Check holder for non-removed battery cases

Benefits