Dual 3D camera system detects dimensional deviations on saw blades during the running process

Topics

2D Metrology

Test Device

3D Inspection

3D Metrology

VisionCommander®

Industries

Machine Building

Application and Solution

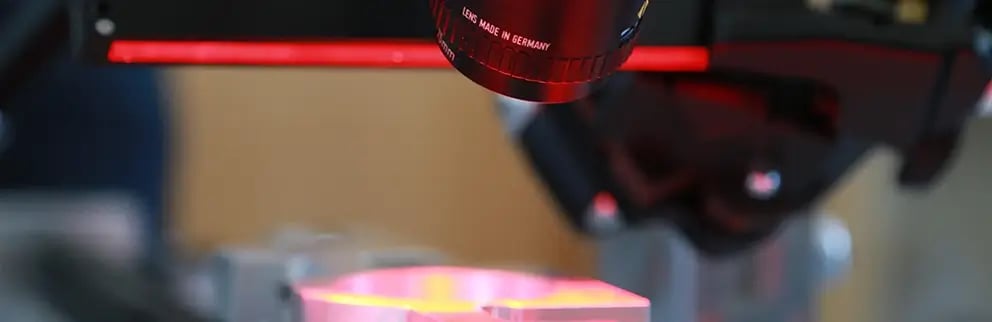

There are many dimensional data on saw blades that ultimately determine the cutting quality and lifespan. For the inspection of diamond saw blades, senswork, together with the company Plattner, has equipped a measuring station with a double-head laser scanner system that measures and records all gear geometries, blade width, cutting width, angularity, diameter, etc. during the run. The evaluation takes place in the VisionCommander® image processing software.

Learn more about VisionCommander®.

Tasks

- Inspection of diamond saw blades

- Measurement of gear tooth geometries, blade width, cutting width, angularity and diameter

Benefits