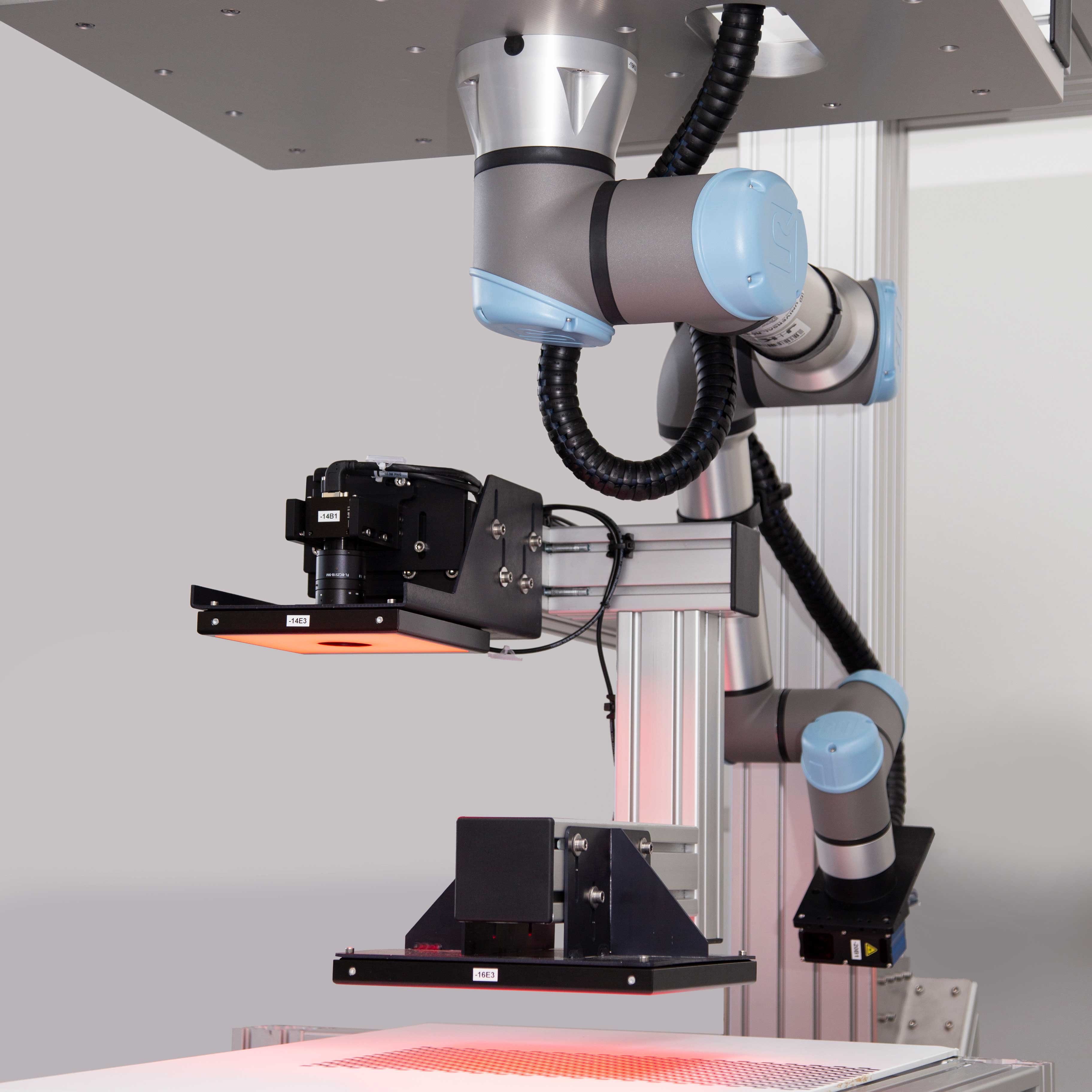

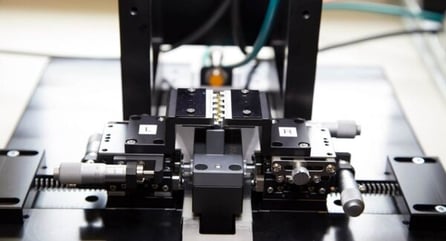

Machine Vision Systems

Turnkey SystemsFind the right turnkey optical measurement or inspection system here. We offer optical inspection and quality assurance solutions ranging from handheld inspection devices to fully automated in-line measurement systems. Thanks to our interdisciplinary teams, our solutions are always scalable and flexibly adaptable to meet new customer needs.

View System Solutions