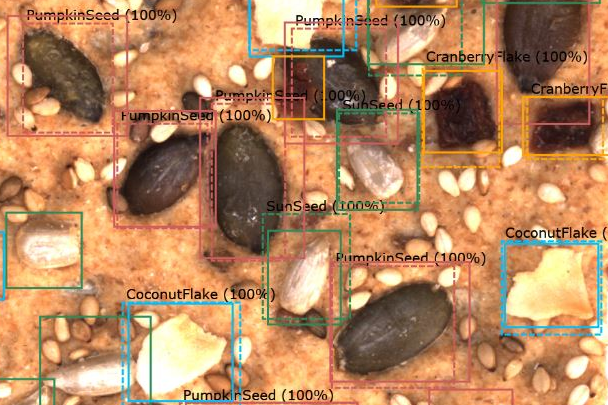

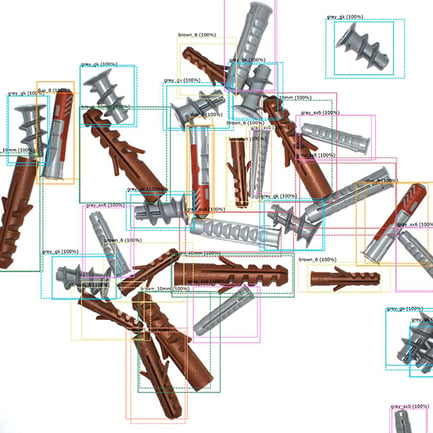

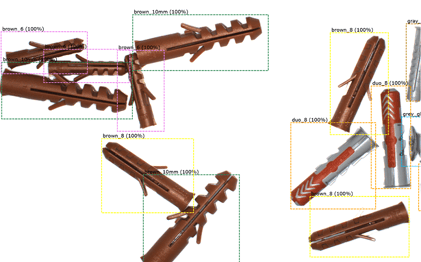

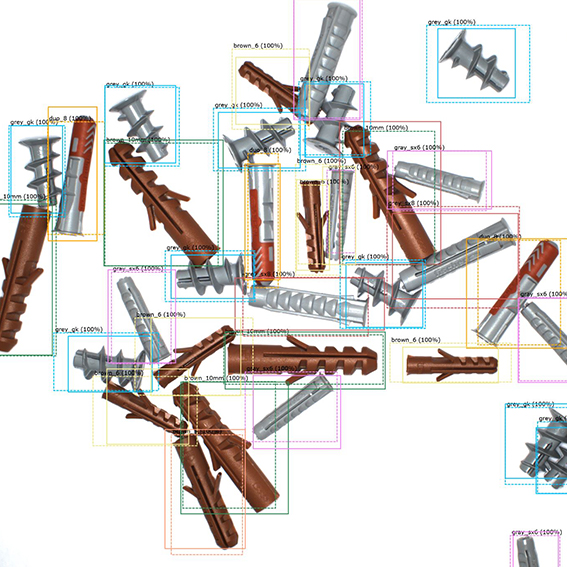

Deep Learning is often the solution for optical quality assurance tasks that were previously considered problematic or difficult to implement. Properties such as reflectivity or transparency of component surfaces, or even complex and varying features such as those found in plants, can be efficiently tested.

As experts in Vision AI, senswork has been developing the Neuralyze® software toolkit. The software platform provides all necessary functionalities required for the implementation of AI applications on image data. In doing so, we place great emphasis on user ergonomics in order to offer both experienced and new users the easiest possible usability. Neuralyze® significantly expands the spectrum of solutions that can be reliably solved with the help of optical inspection and measurement technology.