senswork has developed turnkey camera modules that can be installed in machines with little effort. The VisionUnit shows its advantages especially with rotary transfer machines, where up to twelve different camera systems are installed.

The implementation of camera systems in machines must be well planned. This requires experts who clarify and define various interfaces in advance. This includes the mechanical installation situation in the system, the shielding against extraneous light or the question of how to keep all optical components variable for later fine adjustment.

The coordination is often very time-consuming and there are many stumbling blocks that can make commissioning unnecessarily difficult or delayed. Especially when several cameras have to be implemented on a machine or in a process line, misunderstandings often arise between the machine manufacturer and the system integrator.

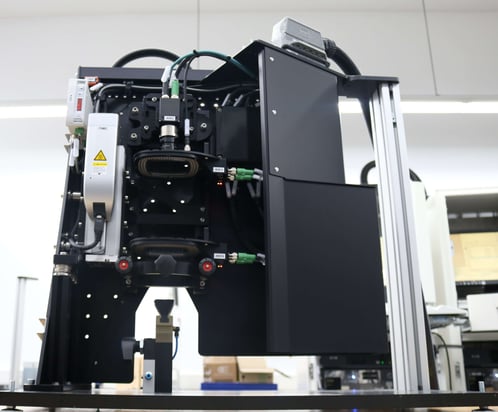

In order to avoid difficulties during the implementation and to simplify the coordination effort between machine builder and integrator, senswork developed the VisionUnit. Thanks to standardized mechanical and electrical interfaces, modular axis systems and focus variation units, the coordination effort is significantly reduced. The plug-and-play solution can be easily installed in machines.

Camera technology, lighting, construction, electrics and software are perfectly coordinated

senswork bundles all of its know-how in the VisionUnit: camera technology, lighting, construction, electrics and software come from a single source and are perfectly coordinated with one another. The compact inspection unit is suitable for multi-camera systems, area, line and 3D cameras. An interim acceptance of the camera modules is possible in advance at senswork. The compact test units are already pre-calibrated for delivery.

In addition to a high adherence to deadlines for projects and a better guarantee of the quality of the end product, the customer benefits above all from the smooth integration of the camera modules. The greatest benefit: A lot of time can be saved in project planning and commissioning - in some cases up to four weeks. "This sometimes shortens the project duration by a third," emphasizes Rainer Obergrußberger, managing director of senswork.

Another advantage: The compact test units are easy to maintain and downtimes are shortened. In addition, extensions to existing machines are possible at any time. Older production systems can also be retrofitted with the technology if necessary.

Press Contact

Hedwig Unterhitzenberger

+49 8677 409958-37

hedwig.unterhitzenberger@senswork.com

senswork GmbH, Gewerbepark Lindach D 3, 84489 Burghausen