Munich, 11. October 2022 – The detection and inspection of transparent polymer surfaces with the smallest qualitative deviations was previously considered a challenge. With a new technology from the company senswork, the transparent so-called LabDisks or Lab-on-a-Chip designs used in medical technology can be inspected for the first time in the production cycle at the manufacturer. The Bavarian company developed the AI-based method as part of the recently successfully completed three-year ControlPlus research project, in which research and development service provider Hahn-Schickard was also involved.

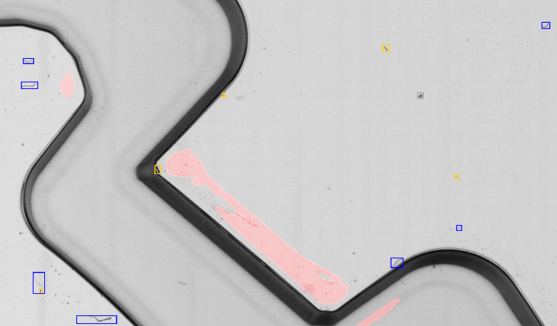

Hahn-Schickard develops test carriers for its partners on which diagnostic analyses are automated by microfluidic structures using centrifugation. For example, PCR detection of the SARS-CoV-2 virus can be performed in around 40 minutes - without manual steps, fully automatically. An innovative testing station developed by senswork enables camera-based quality assurance of the test slides directly in production. A high-speed microscope captures the transparent cartridges with a diameter of approximately 150 mm inline with a resolution of 10 micrometers. On this, senswork's AI software Neuralyze independently detects the structures and dimensions of the fluidic channels and distinguishes liquids, delaminations, and the position of particles and dust. At the same time, the process time is 80% less than the cycle time of the preceding sealing process. With this high speed, the AI inspection station from senswork enables quality assurance of LabDisks in the production process for the first time.

"Both the speed and the flexibility of AI defect assessment would be inconceivable without the outstanding imaging quality we achieve in our system. The optimal meshing of all technological aspects of an image processing system is the result of our extensive experience" tells Markus Schatzl, director of the senswork Innovation Lab. The image processing expert senswork recognized the relevance of artificial intelligence for innovative image evaluation processes years ago. In the Munich Innovation Lab, the company is specifically dedicated to the further development of image evaluation processes with neural networks.

Press Contact

Evelyn Haid

+49 8677 409958-5

evelyn.haid@senswork.com

senswork GmbH, Gewerbepark Lindach D 3, 84489 Burghausen