Optical measurement of battery modules without gaps

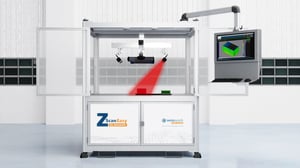

senswork, experts in machine vision systems, will be presenting ZScan Easy, a system for fast 3D inline measurement of battery modules, at Control in Hall 8, Stand 8202. The use of this system guarantees comprehensive quality assurance for prismatic and cylindrical battery cell modules in production. This ensures that all functional and safety-relevant features are 100% fulfilled.

The production of lithium-ion batteries for electric cars is a complex process that involves high material and energy costs. Economical, reliable production with minimal waste is therefore of crucial importance.

Three types of batteries are used in electromobility: the pouch cell, the prismatic cell and the cylindrical cell. They differ mainly in their design and the materials used. senswork focuses on the quality control of prismatic and cylindrical battery modules, which pose special challenges in production due to their design.

The prismatic cell is currently the most common format for electric cars. It is characterized by an almost perfect combination of energy density and safety with a long service life. However, the production of the cell housing is more complex than for the other two types.

The cylindrical cell is a proven technology in battery production. Due to its design, this cell type is limited in the maximum charge quantity. This means that many cells are required for a high output.

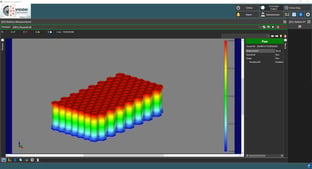

What all cell types have in common is that they have to meet functional and, above all, safety-related requirements. These can often only be checked by measuring the modules in three dimensions in order to avoid risks such as short circuits or overheating.

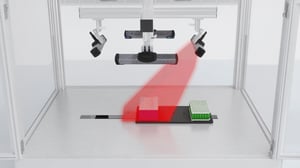

At Control, senswork will be presenting ZScan Easy, a new system for the inline 3D measurement of battery modules using four area scanners from the manufacturer Photoneo, which measures complete battery modules in three dimensions in just a few seconds and transmits the results directly to production.

Based on the senswork VisionCommander® 3D Metrology Framework, typical measurement functions from the GD&T world are used. Both the fast processing of 3D data and the calibration of the individual scanners in a related coordinate space are unique.

ZScan Easy from senswork is characterized by speed, precision and automation capability. It therefore enables efficient quality control throughout the entire production process. Companies can not only save time and costs, but also raise the quality of their battery modules to a new level.

ZScan Easy is suitable for fast 3D inline measurement of battery modules. (Source: senswork)

Press Contact

Hedwig Unterhitzenberger

+49 8677 409958-37

hedwig.unterhitzenberger@senswork.com

senswork GmbH, Gewerbepark Lindach D 3, 84489 Burghausen