senswork presents a manual test station for the inspection of large to very large connector assemblies. The solution is suitable for use in pre-production and small batch production, for spot checks as well as for integration into production lines.

The requirements in connector production are high: Connectors must maintain tolerances of 0.1 millimeters and smaller with process reliability. The trend is toward ever smaller, more compact systems that have to transmit more signals. If batches are faulty, this can cause high costs and lead to annoyed customers. To ensure consistently high quality, connectors must be continuously checked and measured. For this, senswork offers an ideal solution.

With the new manual test station, senswork has developed a turnkey test station for measuring large, complex connector assemblies with different connector types in a single step. This gives manufacturers of connector assemblies greater flexibility in quality assurance. This is because assemblies with many different connector types in particular can be tested efficiently with the solution.

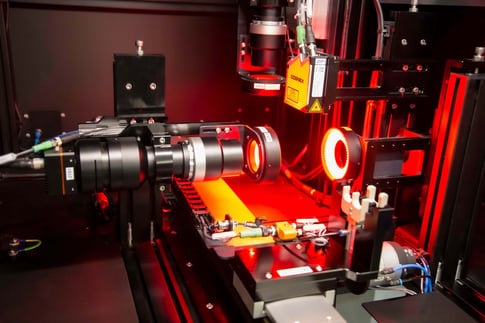

The optical inspection system from senswork measures several hundred pin positions and checks various characteristics, such as correct coding, the planarity of the PCB contact surfaces and the pluggability of PCBs. The "virtual plug gauge" from senswork is used to check the pluggability. Based on the given pin positions, it recognizes in a virtual board image whether the pins fit into the hole grid. Quality control is performed with the high-performance image processing software senswork VisionCommander.

A major benefit is the automatic focusing on different component levels. Whereas cameras with fixed focus settings have to be readjusted to each test object, the high-resolution camera system inspects the connector assemblies at different levels and captures multiple images at different focus levels. This allows different connector types to be inspected without readjustment.

The manual test station consists of a part fixture, a precision axis system, a camera system with a resolution of ten micrometers per pixel, a good part marker and a Siemens control system with touch panel. In addition, it is equipped with safety technology. An NIO box makes it possible to automatically sort out defective parts. With the quick-change system, changeover to other part types takes less than five minutes.

Depending on the testing task and requirements, the manual test station can be customized. The modular design allows the extension of the technical equipment as well as the integration into complete production lines.

Press Contact

Hedwig Unterhitzenberger

+49 8677 409958-37

hedwig.unterhitzenberger@senswork.com

senswork GmbH, Gewerbepark Lindach D 3, 84489 Burghausen