Delamination in composite films can damage the contents of the packaging. One of the reasons for the peeling of foils in Polymer packaging is the formation of bubbles. Up to now, such bubbles could only be identified automatically at great expense. senswork has now developed a technology that uses deep learning to reliably detect tiny bubbles in foils at an early stage.

Nowadays, packaging is used everywhere: in the supermarket for sliced cheese, in clinics for syringes and infusions or in the pharmaceutical sector for tablets. Countless products in the food industry, medical technology and pharmaceuticals are packaged in complex composite films. This means that a mostly deep-drawn polymer container is sealed with a film.

The sealing process step is anything but trivial. Air pockets can arise if the two materials do not lie exactly on top of each other during lamination or if the temperature control during the thermoplastic sealing process is not sufficiently precise. Sealed-in particles can also ensure that the seam is not 100 percent tight. Moisture can also lead to problems. All of this ultimately causes the film to peel off - the packaging is no longer airtight and the products are damaged.

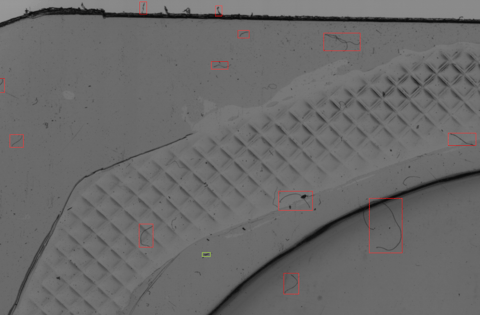

To avoid this, the quality of the products is continuously checked for deviations after packaging in the process line. Most seal inspection systems can detect leaks from 0.25 millimeters or unsealed folds in the seal area. Organic contamination and internal unsealed areas are not recorded.

Until now, the integrity of packaging has been assessed using destructive tests, for example. The packaging is immersed in water and checked for gas bubbles escaping around the seal. The seal seam strength can be measured by pressurizing the package with compressed air until the seal fails. In the case of transparent composite films, quality control for bubbles or contamination with image processing has not yet been possible.

Challenge: Reflective surfaces

The challenge here is that the film surface usually does not have a homogeneous topology and the different material thicknesses refract the light differently. Only the combination of different recording and lighting techniques can the defects be reliably identified. This turning and tilting - for humans a very intuitive approach to the visual inspection of such objects - can only be solved with camera systems with a disproportionately high effort.

From a certain level of complexity, even a set of rules for the clear differentiation and classification of features can no longer be described, which means that a conventional algorithmic solution becomes a distant one. With deep learning, however, it becomes possible to meet this task efficiently - a description of rules is no longer necessary.

Quality assurance with Deep Learning

senswork, an expert in industrial image processing and deep learning, has now developed a technology based on deep learning: Neuralyze reliably and early on identifies air inclusions and delamination in the sealing seam of transparent polymer materials. In particular, contamination with particles or fibers to which microorganisms can adhere are reliably detected with the system.

The intelligent, visual quality control learns to recognize the smallest bubbles and particles in any form with high precision and to interpret what has been "seen". It works as follows: A self-learning method with neural networks is implemented to assess characteristics. A large amount of image data is required in advance for this. In the subsequent training process, the assessment of the characteristics is optimized. When the process is complete, the system is ready for use. It can now automatically ensure the quality and tightness of the weld seams during the seal seam inspection.

Fast, efficient and reliable

The new solution has numerous advantages for the user: Employees no longer have to stand on the assembly line and carry out extensive visual inspections. The technology works quickly, efficiently and reliably. This reduces the error rate and increases productivity in production. “Neuralyze can check packaging in a few seconds,” says Markus Schatzl, head of the senswork Innovation Lab in Munich. "This makes it unique on the market."

Quality assurance with this level of detail can normally only be achieved offline using random samples using microscopy methods. The use of line scan camera technology enables fast image acquisition with a very high resolution. Neuralyze evaluates these very large image data sets with specially optimized algorithms.

In addition to inspecting sealed seams in the food, cosmetics and pharmaceutical sectors, there are a number of tasks in image processing that cannot be accomplished with rule-based methods. With deep learning, the rules of the game have changed and much is possible that previously had to be rejected as not solvable. Intelligent image processing is particularly suitable for applications with complex features and many variants

Press Contact

Hedwig Unterhitzenberger

+49 8677 409958-37

hedwig.unterhitzenberger@senswork.com

senswork GmbH, Gewerbepark Lindach D 3, 84489 Burghausen