Burghausen, 07 June 2022 – The KIKoSA project at Friedrich-Alexander-Universität Erlangen-Nürnberg aims to monitor and optimize the quality of hairpin welds inline using AI-supported 3D measurement technology. This will make the production of electric motors significantly more efficient.

33,655 electric vehicles were registered in Germany in September 2021. This brings their market share to 17.1 %, overtaking the number of newly registered diesel cars for the first time with a market share of 15.9 %.

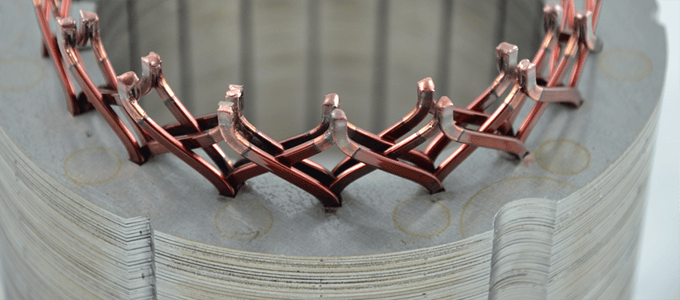

In the manufacture of electric motors, a large proportion of OEMs rely on stators with hairpins - U-shaped bent plug-in coils made of coated flat copper wire - instead of the classic drawn-in round wire winding. This technology offers decisive advantages: The motor has high power at low weight and the stators can be produced in large quantities.

Hairpins also have advantages over wound coils in terms of the inspectability of the production process. However, there are currently no image processing approaches capable of evaluating hairpin welds in their three-dimensional structure and with sufficient accuracy in the production cycle.

Around 160 to 220 hairpins are welded together during assembly. The welding process must be safe, stable and highly accurate. Otherwise, it can have a major impact on the quality of the stators and thus the engine. Since this work step depends on numerous factors, conventional quality assurance processes reach their limits here.

Goal: Inline solution for process-reliable laser welding

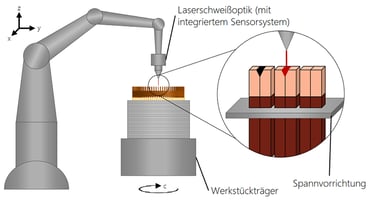

Researchers at Friedrich-Alexander-Universität (FAU) Nuremberg-Erlangen and partners from industry are therefore working on a fast, cost-effective testing method in the project "Artificial intelligence for process-safe laser-based contacting of stators for electric drives" (KIKoSA), with which the quality of welded joints can be monitored 100 percent inline.

Involved in the project are the Chair of Manufacturing Automation and Production Systems (FAPS) at FAU, the companies Ancud IT, BMW, GROB-WERKE, Lessmüller Lasertechnik and senswork. KIKoSA is funded by the Bavarian State Ministry of Economic Affairs, Regional Development and Energy. The three-year research project will run until the end of August 2023.

To ensure an accurate and stable laser welding process, senswork GmbH is developing a 3D inspection system based on artificial intelligence (AI) as part of the project. The deep learning approach is crucial because it enables the modeling of complex relationships that can no longer be adequately described by simple rules. By categorizing deviations from the optimum weld seam characteristics, conclusions can also be drawn about upstream process steps.

The task of senswork includes the development of a novel multi-sensor 3D module with integrated kinematics as well as the conception, development, and implementation of data evaluation within the framework of an innovative hardware and software architecture. After an evaluation phase in the laboratory, the concept will be integrated in the production environment.

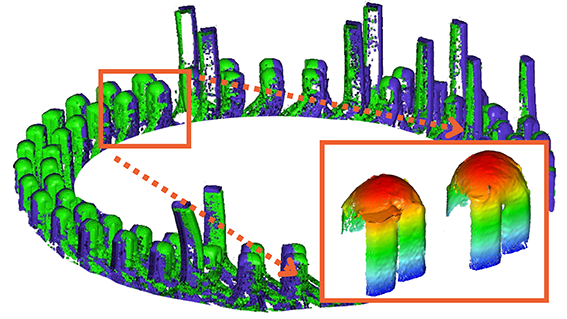

High accuracy with few training images

To assess the quality of the laser welding process, high-resolution data of the welding spots is captured with the help of a 3D sensor module and evaluated using Deep Learning. For this purpose, the expert in the field of industrial image processing implements a self-learning method with neural networks. For the training of the neural network, welding defects with different process parameters were intentionally generated. A total of 660 3D data sets were initially available. Through augmentation - i.e. synthetic modification of existing data - the number of input data sets was again increased to about 2,000.

The concept of a self-regulating laser welding process is also being pursued with KIKoSA. With AI-supported defect inspection in 3D, laser welding can be efficiently automated and at the same time qualitatively safeguarded. In view of the current research results, it is reasonable to assume that the methodology will contribute to a leap in quality in electric motor production.

Press Contact

Evelyn Haid

+49 8677 409958-5

evelyn.haid@senswork.com

senswork GmbH, Gewerbepark Lindach D 3, 84489 Burghausen