Optical inspection systems have been successfully used in production plants for automated quality assurance for decades. Advances in the field of artificial intelligence (AI) have recently drawn more attention to this field.

AI offers a range of new analysis methods that were previously not available in industrial image processing. This combination is therefore also referred to as Vision AI. The importance of AI in the quality assurance of production processes is constantly increasing due to these new possibilities.

Implementing AI in manufacturing

In AI processes on image data, the neural network learns the properties of a feature itself through targeted training. Previous, so-called rule-based methods, on the other hand, are based, for example, on the description of the geometric boundary conditions by a developer.

As a result, neural networks are much better able to capture subtle properties of features and to include the relevance of boundary conditions in the assessment. This way, it will be possible to evaluate properties more flexibly and robustly at the same time - both in relation to product characteristics that have not occurred before and unknown situations on a production line.

Numerous test tasks that were previously difficult or impossible to solve can therefore be successfully implemented with AI.

Vision AI in practice

There are practical applications for Vision AI in all industrial sectors. Especially for objects with characteristics that are difficult to describe or a large range of variations in the characteristics, AI has proven to be the silver bullet. This includes metallic surfaces of all kinds, bulk goods, textiles, and foils, but also naturally formed or grown goods such as food and plants.

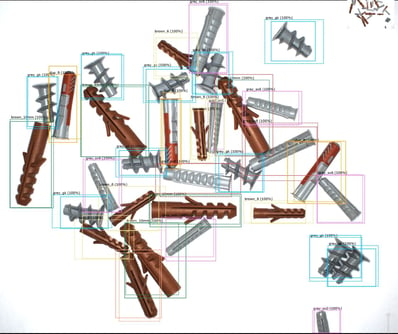

A practical example is the identification and sorting of dowels. With AI-based image processing, it is possible to identify different components using an object detection model. Overlapping or touching objects can also be detected without errors.

Seizing opportunities with AI

In quality control, manual visual inspections are still common to categorize and classify products. However, the visual inspection has the disadvantage that it depends on the experience, daily form and concentration of the inspector and is therefore error prone. The human eye has so far been difficult to replace, especially for complex inspection tasks. With the help of AI, however, more and more of these previously almost impossible test processes can now be automated.

There are numerous advantages for users with Vision AI: The monotonous work of the employees who carry out complex visual checks on the assembly line is no longer necessary. Automated systems work quickly, efficiently, and reliably. As a result, the error rate decreases and productivity in production increases.

AI for segmentation tasks

In addition to classification, segmentation, i.e., the precisely defined identification of objects and properties, is a key area of responsibility in quality assurance using image data. It is often not only important to identify bad parts, but also to precisely determine the position and size of the defect area.

With conventional, rule-based image recognition methods, static boundary conditions often must be assumed for successful analysis. In industrial practice, these are difficult to guarantee over long periods of time. Fluctuating lighting conditions or tolerances in the feed, for example, then have a negative effect on the test and lead to incorrect results.

AI-based processes, on the other hand, can be designed much more flexibly and are able to deal with such fluctuations. The robustness of AI processes is also a clear advantage in the case of other interference, such as those that can arise on reflective, corroded, or inhomogeneous objects.

Detecting flaws on metallic surfaces

A common application is the inspection of metal surfaces. Typical problems that lead to rejects are scratches, cracks, or cavities. The error patterns are characterized by a high variance in characteristics and largely elude a rule-based analysis. By using Vision AI, surface defects can be identified correctly on image data despite the blurred defect characteristics.

The application of classic, rule-based image processing methods for such tasks is associated with a great deal of effort and is difficult to reliably adapt to the different error characteristics in the long term. AI-based methods, on the other hand, can deal more flexibly with varying errors and lighting conditions. The use of AI offers a more flexible, faster, and more cost-effective automation solution that is less susceptible to faults in difficult environmental conditions.

Outlook: Systems will become more intuitive

A promising recent development related to Vision AI systems is the concept of Machine Learning Operations (MLOps). If domain specialists are currently still required when it comes to continuous testing, monitoring, and validating a system, MLOps will simplify these activities significantly.

In the future, the entire life cycle of an AI application will be integrated into the control and operating environment with the help of more transparent and user-friendly software. For users, the AI in image processing can be operated easily and intuitively - without the specialist in the background.

Rule-based image processing

Despite the many advantages of Vision AI, the tried-and-tested, rule-based methods for analyzing image data are by no means losing their importance. The advantages of this approach lie elsewhere, for example in terms of execution time, traceability or validation and parameterization. A well thought-out combination of both approaches will remain essential for solving demanding tasks in quality assurance in the future.

About us

The senswork Innovation Lab in Munich deals with AI in image data analysis and develops processes and software based on neural networks for industrial use. senswork is a specialist for optical measuring and testing systems. The company offers fully integrated systems from a single source: from the control cabinet to camera technology and image analysis. Customers include car manufacturers, machine and plant builders and the electronics industry.

Press Contact

Hedwig Unterhitzenberger

+49 8677 409958-37

hedwig.unterhitzenberger@senswork.com

senswork GmbH, Gewerbepark Lindach D 3, 84489 Burghausen