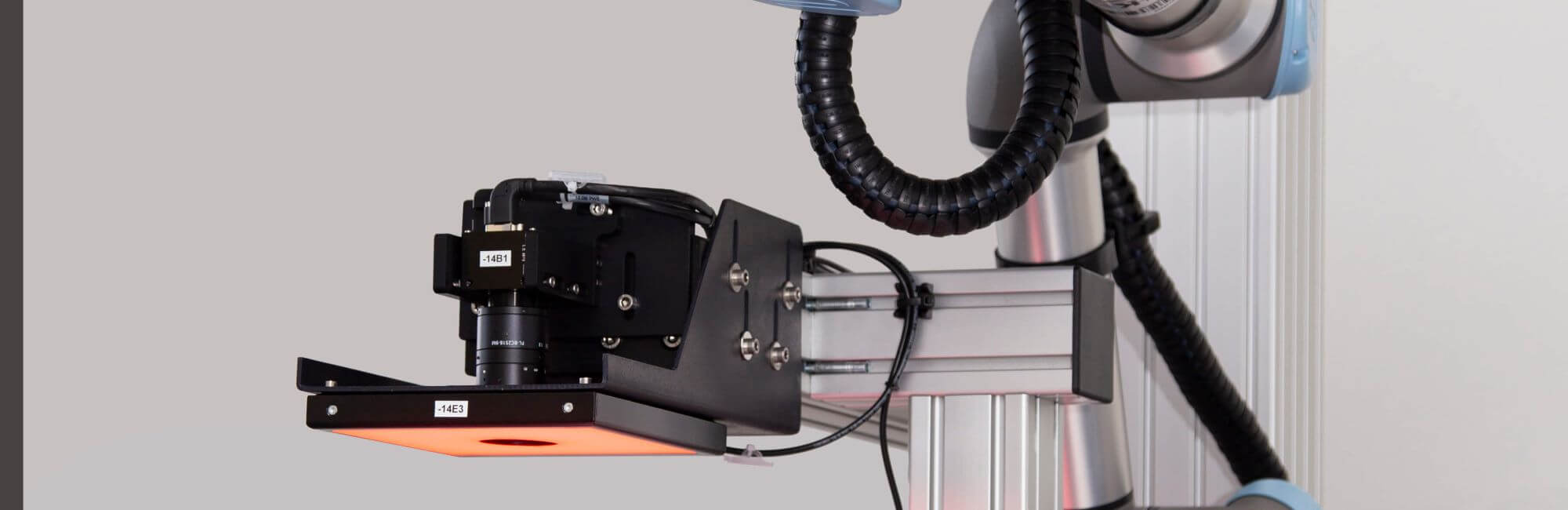

Machine Vision Solutions for Your Industry

Our turnkey machine vision solutions secure manufacturing processes in a wide range of industries.

Many Sectors Benefit from Machine Vision Solutions

With reliable, low-maintenance machine vision solutions, we ensure the quality of products in a wide range of industries. You too can benefit from this. Contact us even if your industry is not listed here. Our solutions are versatile, and we will be happy to advise you!

Automotive

Quick & precise testing

Automotive

Quick & precise testing

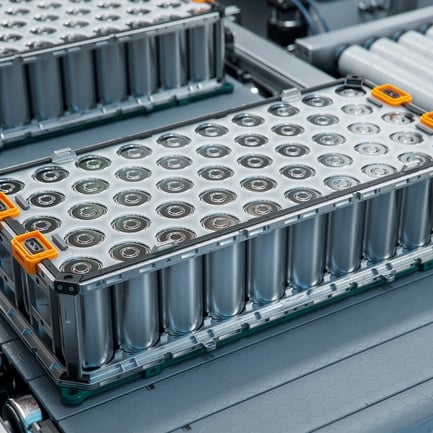

E-Mobility

Varied solutions for electric vehicles

E-Mobility

Varied solutions for electric vehicles

Medical Technology

Highest demands on precision

Medical Technology

Highest demands on precision

Electronics

For high performance

Electronics

For high performance

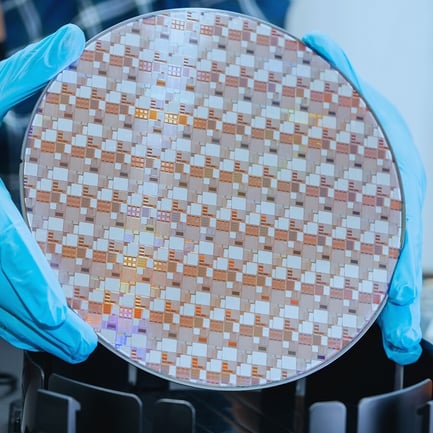

Semiconductors

Non-contact testing in wafer production

Semiconductors

Non-contact testing in wafer production

Machine Building

Automated inspection processes

Machine Building

Automated inspection processes

Polymers

Inspect complex shapes & consistencies

Plastic Processes

Inspect complex shapes & consistencies

Food & Beverage

Ensure perfect shape & fill quantity

Food & Beverage

Ensure perfect shape & fill quantity

Cosmetics

Quality assurance through camera technology

Cosmetics

Quality assurance through camera technology