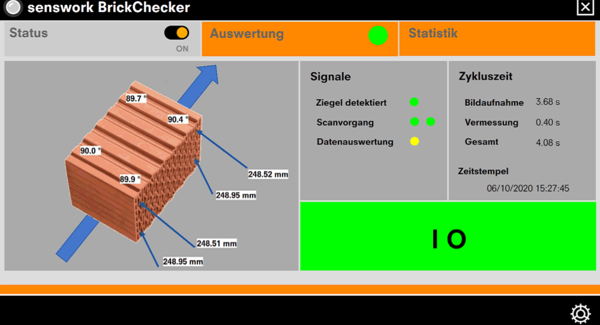

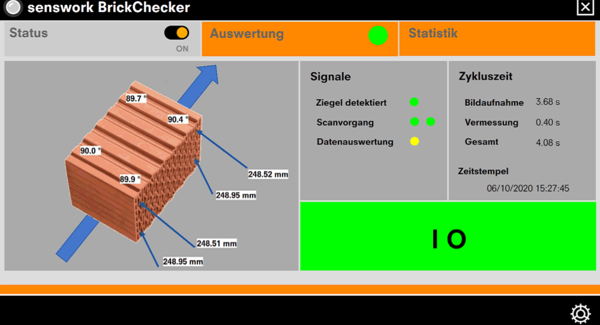

A system for 3D measurement uses laser triangulation to ensure the dimensional accuracy and squareness of clay bricks.

Our optical 3D measurement technology brings the CMM to manufacturing

Measure products in real time without contact

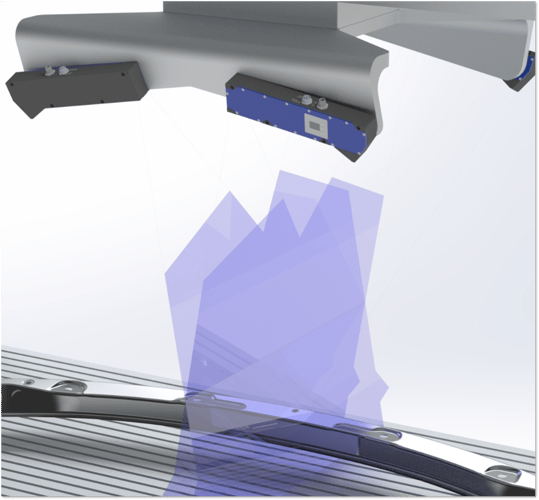

Optical 3D inline metrology changes the rules of the game in quality assurance by minimizing or even eliminating time-consuming measurements in the measuring room. With its speed, precision and automation capabilities, optical 3D inline metrology enables more efficient quality control during the production process. Thanks to this innovation, businesses can not only save time and money, but also raise the quality of their products to a new level.

Are you looking for 3D inspection for production? Then visit our 3D inspection page.

We are the right partner

Optical 3D metrology provides fast and accurate measurement of geometric dimensions, which is much more efficient than tactile methods. However, the selection of the most appropriate technology depends on the task to ensure both the required accuracy and speed during the production process. It is also important to take into account factors such as temperature variations, contamination and vibration in the production environment.

We are your specialists for the development of customized 3D inline measurement systems, which we accompany from the planning phase to acceptance. Rely on our expertise to make your 3D measurement project a success.

A comprehensive portfolio of technologies and functions

We always select the optimal scanning technology for each application, regardless of the manufacturer. Our priority is the absolute accuracy of the scanners and the use of appropriate calibration methods to ensure measurement capability in production.

Our comprehensive 3D toolbox enables fast processing of point clouds without compromise:

Experience the power of our algorithms, optimized for speed without compromising accuracy, especially for use in manufacturing. All integrated into the VisionCommander® software.

Key points for implementation

Space Requirements: The installation of the 3D measurement system may require structural modifications and additional space requirements.

Calibration & Accuracy: Repeatable and automatic calibration of the system is critical for accurate measurements.

Interfaces: Integration into existing production systems requires appropriate control interfaces.

Measurement Programs: The measurement strategy must be derived from the (tactile) comparison measurement in order to also achieve comparable results.

Environmental Conditions: The system must be robust enough to operate in demanding production environments with vibrations and temperature fluctuations.

Qualification of Personnel: The staff must be specially trained to use the 3D measuring system effectively.

... it is the foundation of a reliable measurement

Thanks to our calibration methods developed over many years with sphere targets on carbon plates, sensors with free spatial arrangement can be calibrated and scan data from several scanners can be spatially merged. This principle can be applied to any number of spatially differently arranged laser scanners. We attach great importance to the fact that our calibration targets can be easily and effectively inserted for control or recalibration even during running production. The calibration normally runs fully automatically and guarantees continuously stable values even under fluctuating environmental conditions.

We deliver corresponding measurement records from certified measurement service providers for each calibration target. On request, we can have calibration standards measured by DAKKS-certified institutes in order to best meet the QA requirements of our customers.

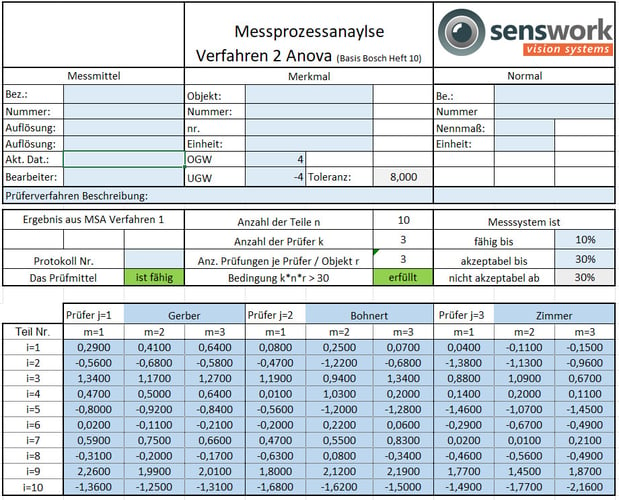

MSA prove the achieved accuracy of a measurement system

The selection of the appropriate MSA standard depends on the respective industry and the specific requirements. In many cases, several standards are combined to perform MSA according to individual needs. The correct application of these standards is crucial to ensure accurate and reliable measurements and to improve the quality of products and processes.

We accompany with you the execution of MSAs (measuring system analyses) in the validation of our optical measuring systems. If required, we can also provide corresponding calculation tools.

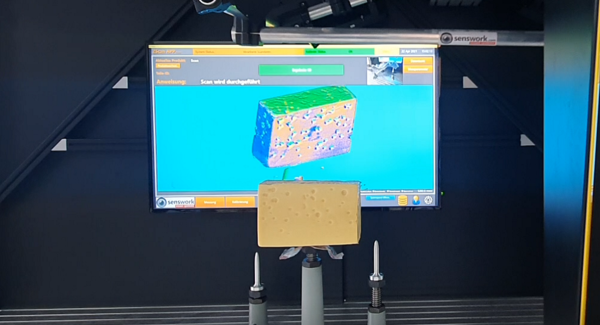

The fast & versatile 3D measurement system convinces at Magna

A system for 3D measurement uses laser triangulation to ensure the dimensional accuracy and squareness of clay bricks.

The ZScan 3D scanner from senswork supports the volume determination of food products on the conveyor belt.

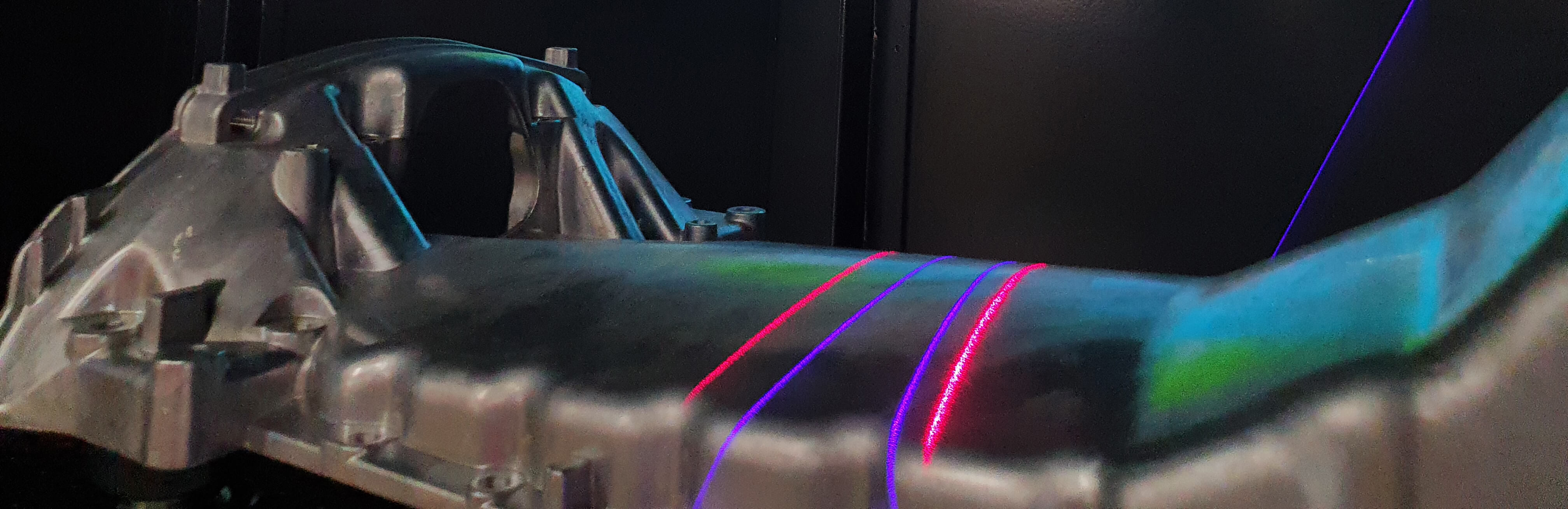

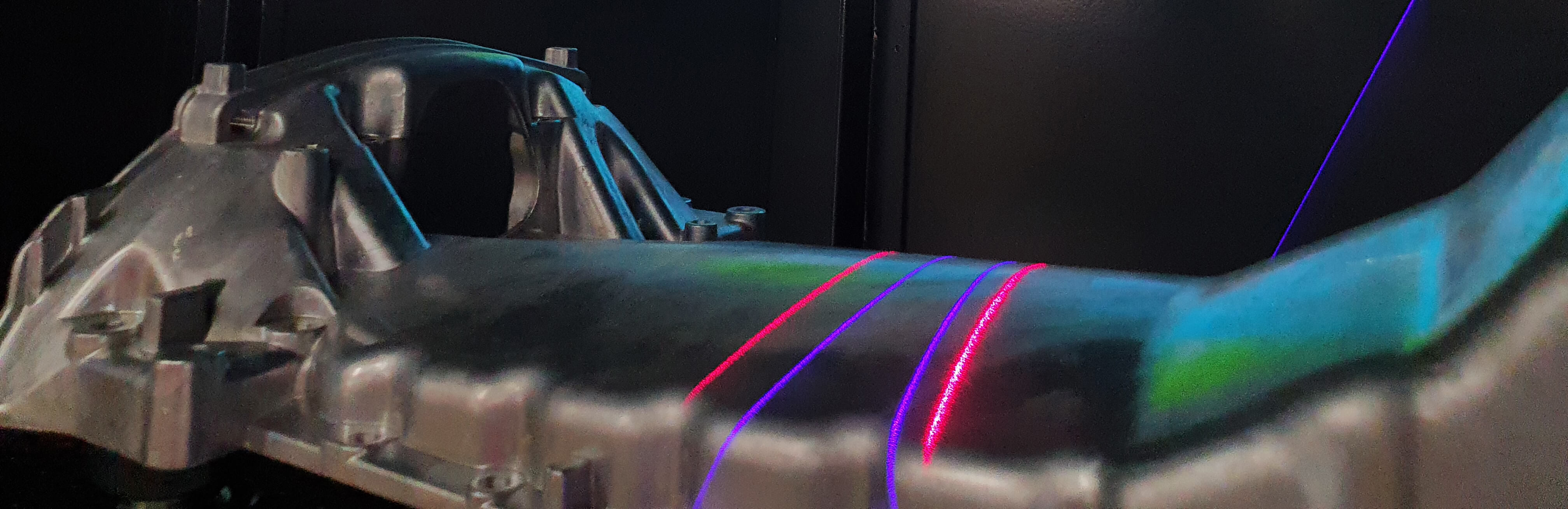

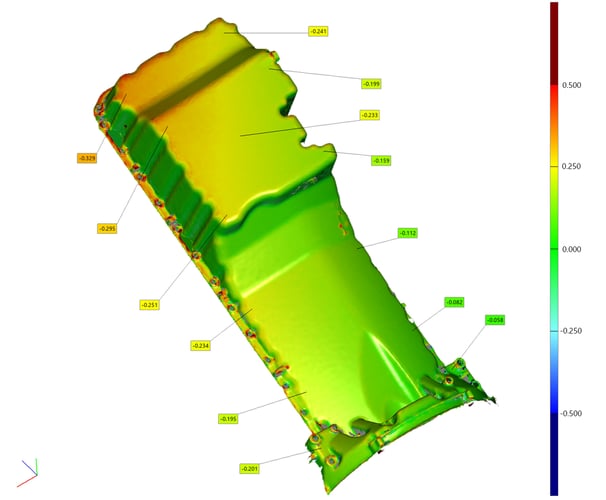

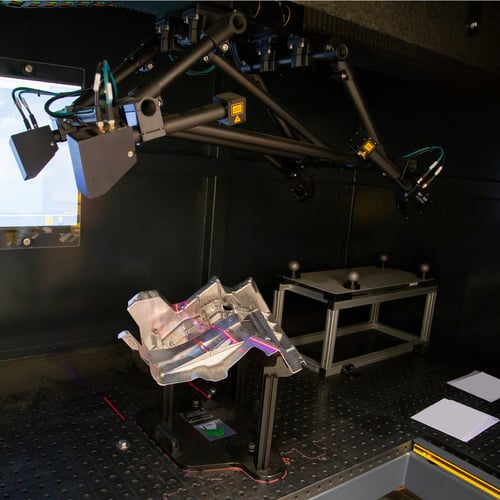

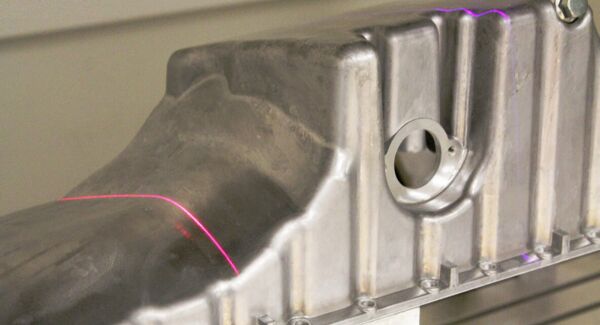

Quality assurance in the automotive industry: Learn how senswork measures large aluminum assemblies and matches them with CAD file data.

Contact us!