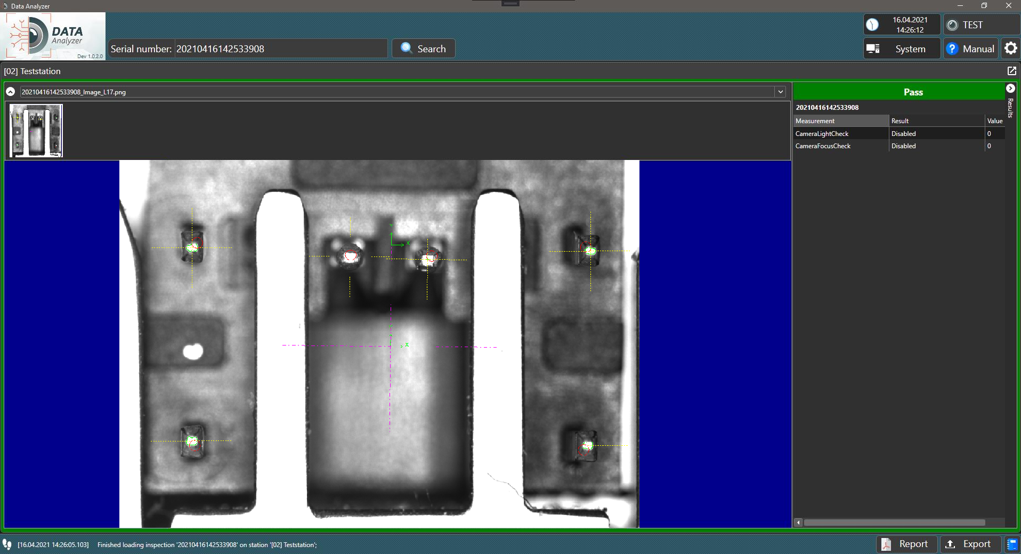

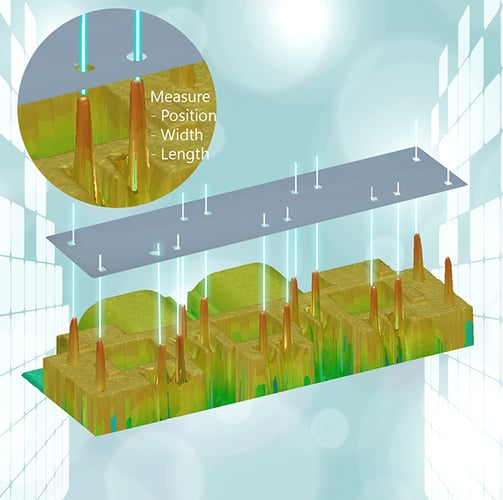

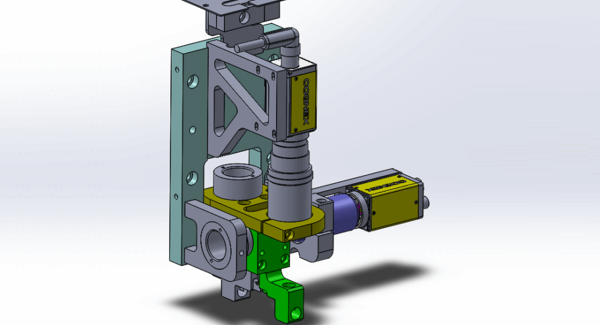

The senswork measuring system inspects cutting contacts on a connector assembly and eliminates the need for mechanical testing.

High precision measurement of connectors

We guarantee the highest quality in the inspection of connectors and connector assemblies.

The demands in connector manufacturing are high: Connectors must maintain tolerances of 0.1 millimeters and smaller with tight cycle times.

Optical measurement of connectors in production is critical for quality and reliability. It ensures exact inspections of dimensions and tolerances, compliance with industry standards and norms. It also checks quality parameters such as contact spacing and alignment. It further detects even the smallest defects, automates inspection, and ensures traceability through documentation. This practice contributes to overall defect reduction, increased efficiency, and cost savings.

For manufacturers of electronic assemblies, it is essential that testing can be easily integrated into the production line to ensure efficient production.

Machine Vision in connector manufacturing

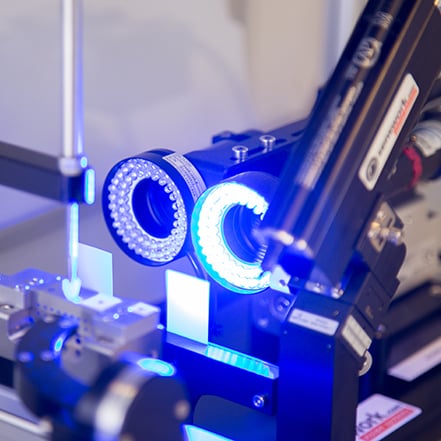

Recognising connector pin tips can be a challenge with conventional image processing methods. With the object recognition tool of our Neuralyze® Vision AI software, this process is simplified.

Images of connector pins can be added to the smart labelling tool with just a few mouse clicks. Around 100 examples are sufficient to ensure that individual pins are later found in the images with a sufficiently accurate boundary - even with strongly fluctuating contrast, asymmetrical reflection or slightly varying pin sizes.

Whether automotive, medical technology or mobile phone connectors - we offer manual test stations and fully automated inspection systems for testing various connector types.

Circular Connectors

Circular Connectors

Board-to-Cable Connectors

Board-to-Cable Connectors

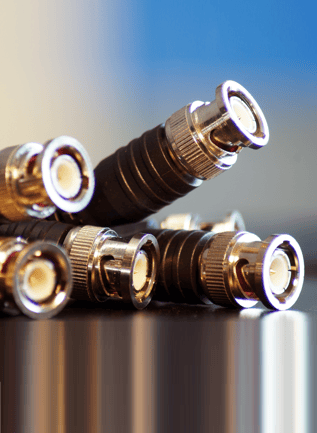

RF Coaxial Connector

RF Coaxial Connectors

Power Connector

Power Connectors

Data Connector

Data Connectors

Miniature Connectors

Miniature Connectors

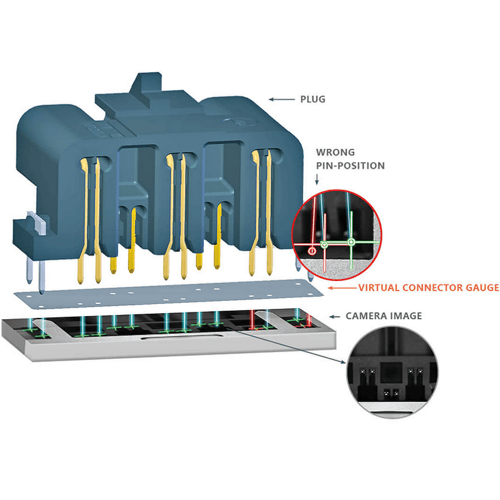

PCB Connectors

PCB Connectors

Fiber Optics

Fiber Optics

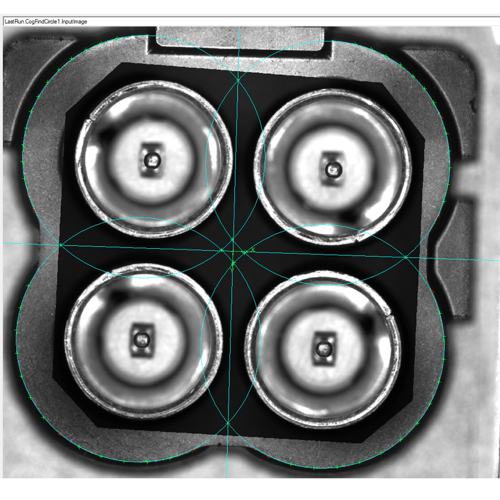

The Virtual Connector Gauge is our unique inspection tool for checking the pluggability of PCB connectors - quickly and without contact.

senswork's virtual connector gauge uses high-resolution cameras and a sophisticated software tool to create an accurate image of the board or socket and check it against the detected pin pattern of a connector. This non-contact approach is flexible and can be used for different connector types without wear or damage to the pins. This provides fast and reliable quality control even for a wide variety of connector types without mechanical setup.

Here is what our connector inspection measurement and test systems have to offer

The senswork measuring system inspects cutting contacts on a connector assembly and eliminates the need for mechanical testing.

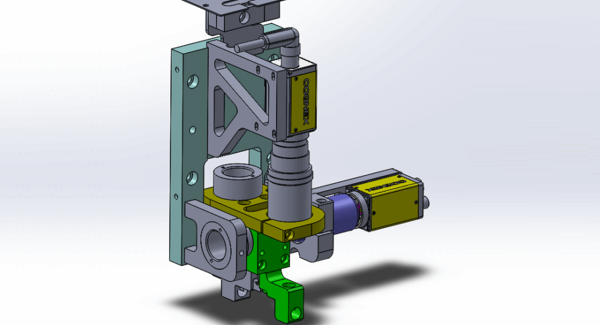

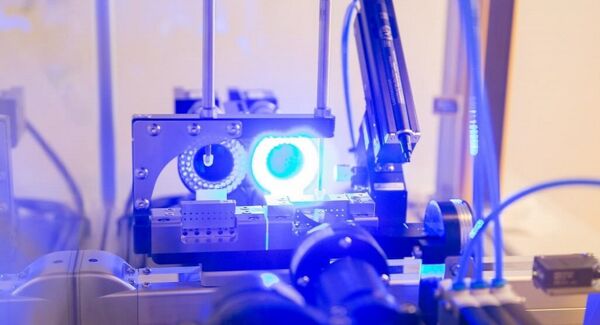

Get an insight into our manual test station with 3-axis system for automotive connector assemblies. Guaranteed quality.

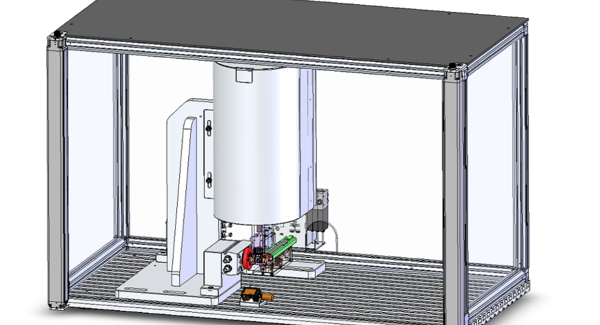

A senswork test system measures the coding, tumble circuit and pluggability of the PCB side of Fakra connector assemblies.

Contact us!