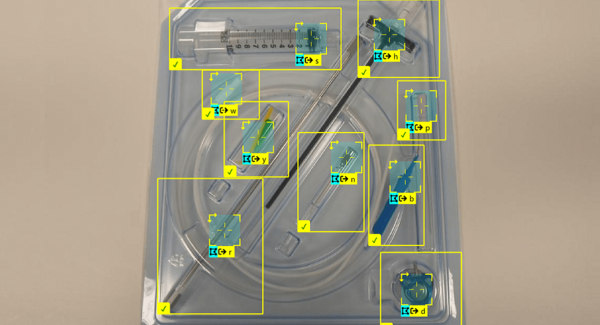

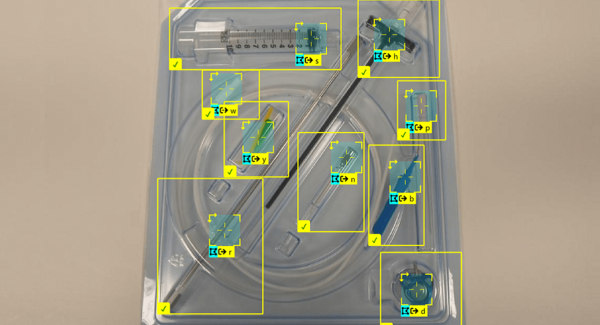

Quality assurance in medical technology: Deep Learning is used to reliably verify the completeness of first aid kits.

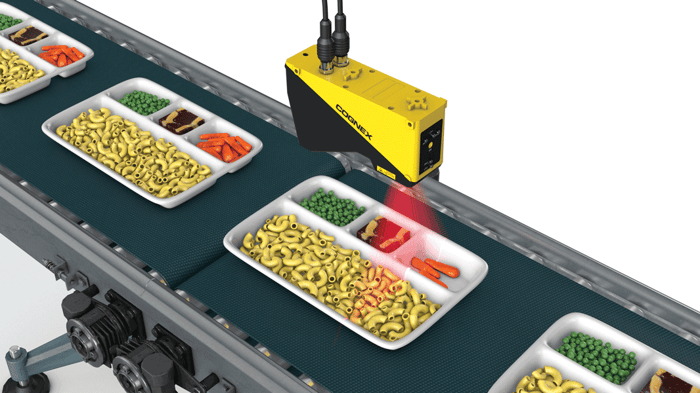

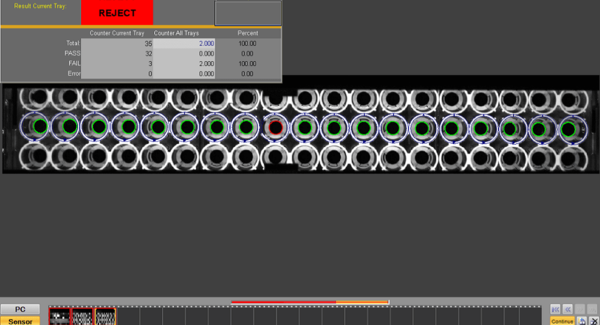

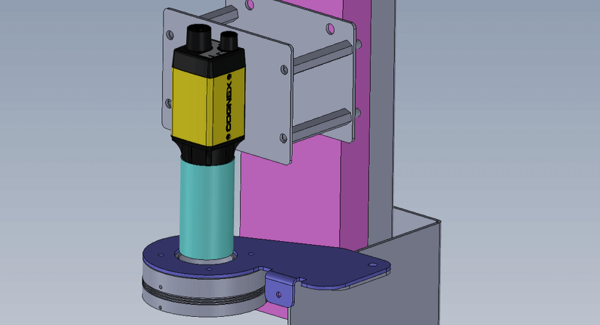

Product inspection prior to the final step of the final packaging process

Color, shape and position verification, sorting, counting

Final product inspection is the keyword for completeness check applications, in automatic sorting or counting:

This is just a selection of possible inspection tasks in fully automated final inspection that we can solve with our turnkey image processing systems.

Quality assurance in medical technology: Deep Learning is used to reliably verify the completeness of first aid kits.

In battery case production, the inspection of washtrays is very important. Our camera system helps with defect detection.

Our metrology system enables the testing of lubricant application on automotive assemblies and provides a stable evaluation.

Contact us!