No axle required

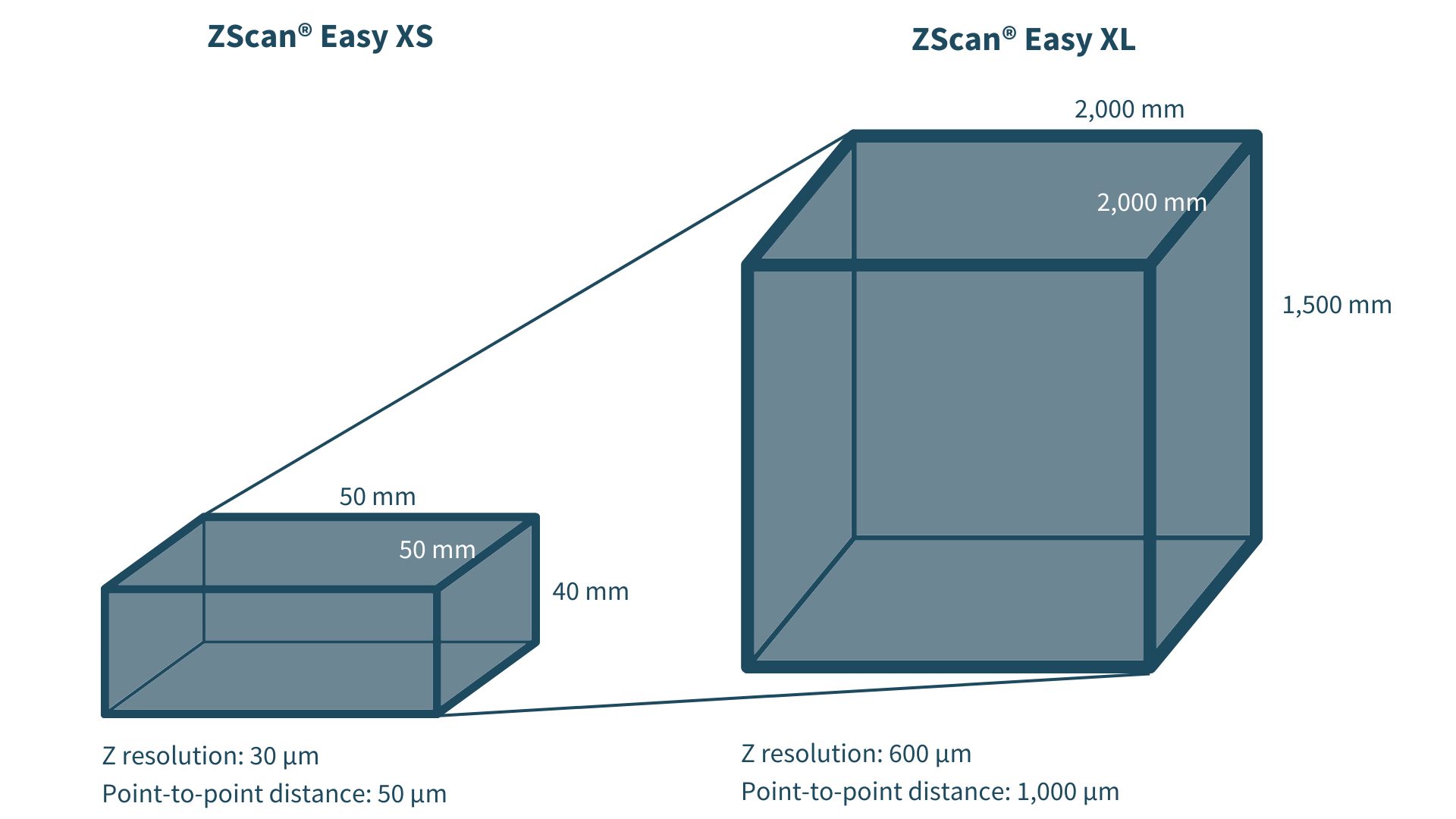

Static ProcessZScan® Easy captures the measurement object in 3D with high resolution and precision. The object is not in motion during the measurement process.

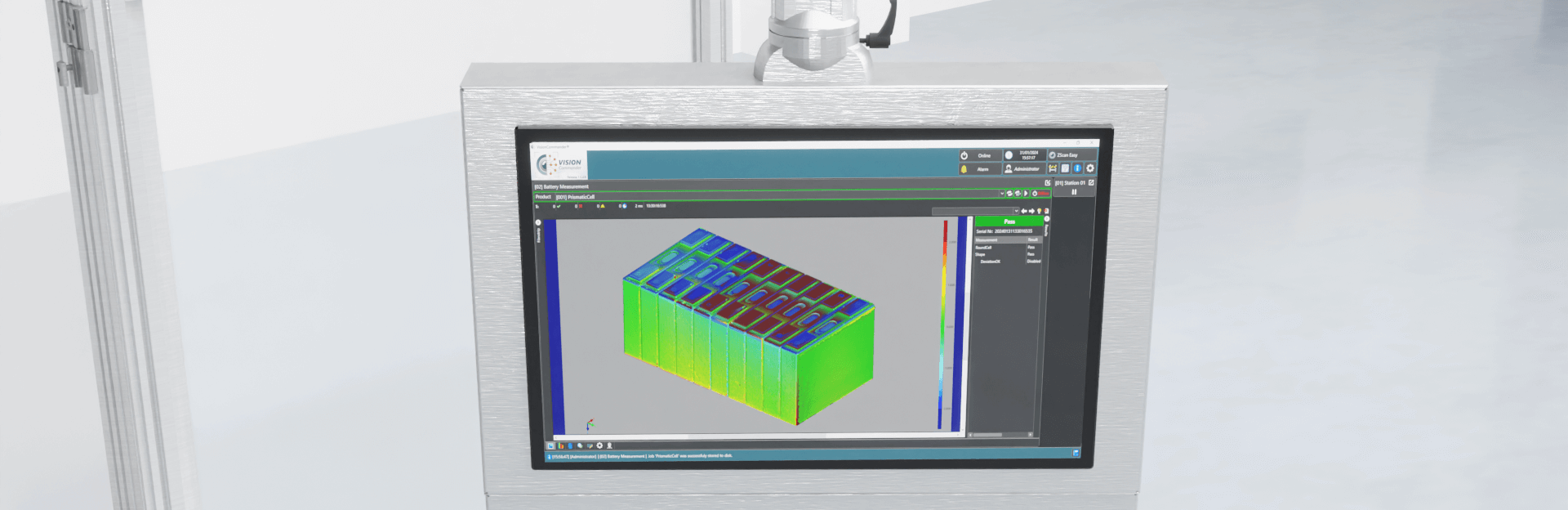

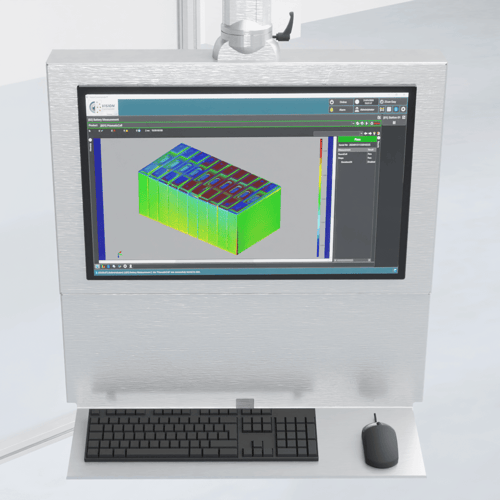

3D measuring system for the inline measurement of parts

With ZScan® Easy, parts such as battery cells can be scanned quickly and precisely in 3D. Automated 3D measurement and inspection take place seamlessly within seconds, directly in the production environment.

With the ZScan® Easy 3D measuring system, the dimensional accuracy of parts can be checked directly during the production process. Within seconds, a component is scanned and compared with its CAD model in 3D. This enables reliable quality control of each individual object in a matter of seconds, without the need for re-inspection in the measuring room. ZScan® Easy also offers the advantage that the parts can be fed in both manually and automatically.

Quality assurance directly on the production line

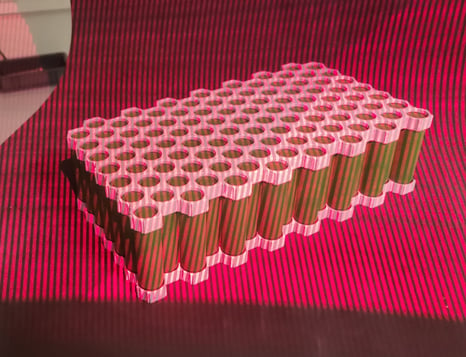

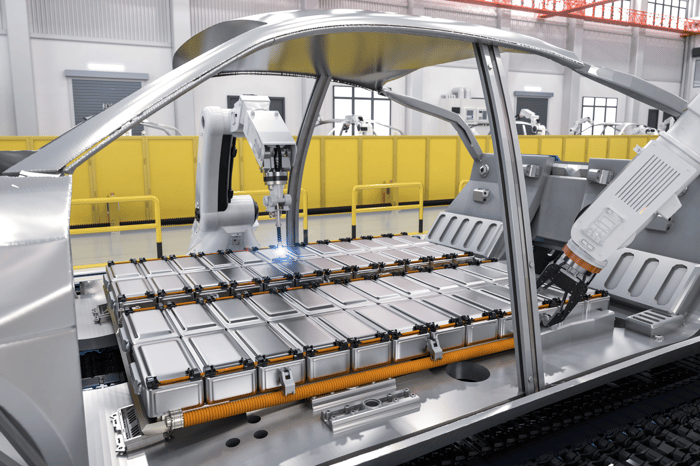

The production of lithium-ion batteries for electric cars is a complex process that involves high material and energy costs. Economical, reliable production with minimal waste is therefore of crucial importance.

With ZScan® Easy, senswork offers a system for the inline 3D measurement of battery modules using up to eight area scanners. In just a few seconds, ZScan® Easy measures complete battery modules in three dimensions and transfers the results directly to production.

Measure 100 % of the parts in the line cycle

Scan objects in just a few seconds

Static measuring system for 3D inline measurement

Up to 12 million 3D measuring points per individual scan

Particularly suitable for (approximately) cubic test objects

Product Guide

Utilize the potential

Production can be easily optimized using the measurement data generated by ZScan® Easy. The measurement data can be:

Furthermore, ZScan® Easy can automatically transmit correction parameters to upstream machines during the ongoing process, which has a positive effect on production quality. It is also possible to transmit the data to downstream machines, which carry out further steps based on the data.

Examples of how you can benefit from ZScan® Easy in your industry

Battery Cells

3D Inspection Electromobility

Battery Cells

3D Inspection Electromobility

Stamped and Bent Parts

Automotive 3D Inspection

Stamped & Bent Parts

Automotive 3D Inspection

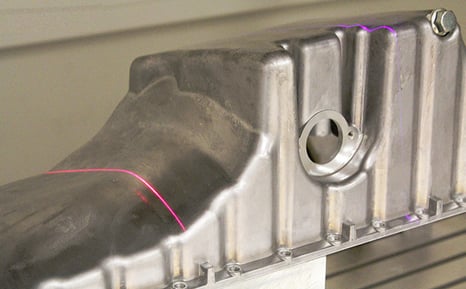

Aluminum Die Casting

Automotive 3D Inspection

Aluminum Die Casting

Automotive 3D Inspection

Several 3D surface scanners capture parts such as battery cells with virtually no shadowing. The associated VisionCommander® measuring software enables the cells to be measured quickly in just a few seconds.

This is what ZScan® Easy does in battery cell production:

ZScan® Easy impresses with many unique selling points

No axle required

Static ProcessZScan® Easy captures the measurement object in 3D with high resolution and precision. The object is not in motion during the measurement process.

Simple and tried-and-tested

Inline CalibrationContinuous calibration ensures that the measurement results are consistent and precise.

No photogrammetry markers needed

Works without MarkersFor the optical 3D measuring system, you do not need any reference points for image analysis and calculation of the 3D coordinates.

Contact us: Leave us a message