100% Measurement of Clay Bricks during Production

100% high-quality bricks

Detect quality problems early on – with the precise BrickChecker 3D measuring system

During the production of clay bricks, precise monitoring of parallelism, perpendicularity, and dimensional accuracy is essential. senswork’s BrickChecker—an advanced optical 3D measurement solution—enables comprehensive, inline inspection of various brick formats directly within the manufacturing process. This ensures enhanced quality assurance, reduced scrap, and greater process transparency.

Quickly and accurately measure clay bricks:

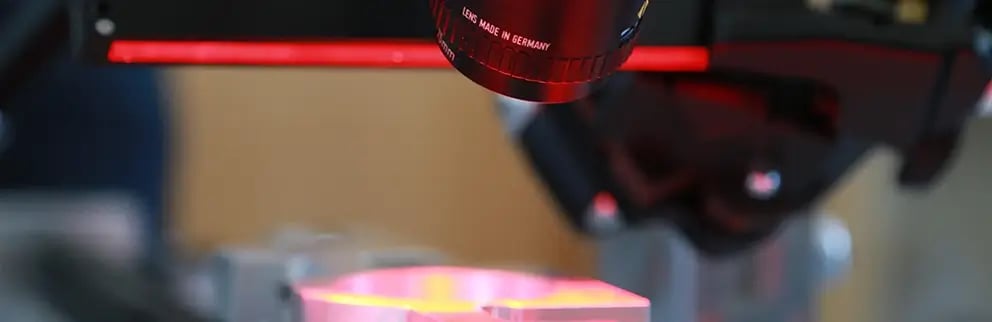

- High-resolution optical 3D measuring system specifically for ground clay tile surfaces

- Detection of flatness, squareness, and parallelism in just a few seconds

- 360° scan using state-of-the-art dual-sensor 3D laser scanning technology

- Measuring resolution: 0.1 mm

- Suitable for a wide variety of tile formats

Benefits

What the senswork BrickChecker has to offer

High-resolution, fast 360° inspection of all brick dimensions, flatness, parallelism, and squareness

Vibration-tolerant measurement during ongoing production without stopping or retooling, directly in the product line

Robust housing protects against harsh environments – suitable for ceramic production environments

Automatic testing, trend analysis, meaningful visualization, simple parameterization

Quickly and easily check clay tiles

3D measurement of ground flat surfaces in seconds during production

Fully automatic inline measurement process

- Direct integration into the production line

- Measurement during ongoing production without stopping or retooling

- Process-stable results even in vibration-intensive environments

Industrial-grade design

- Robust housing and protection against dust, vibrations, and temperature fluctuations

- Suitable for harsh ceramic production environments

- Low-maintenance operation thanks to protected optics

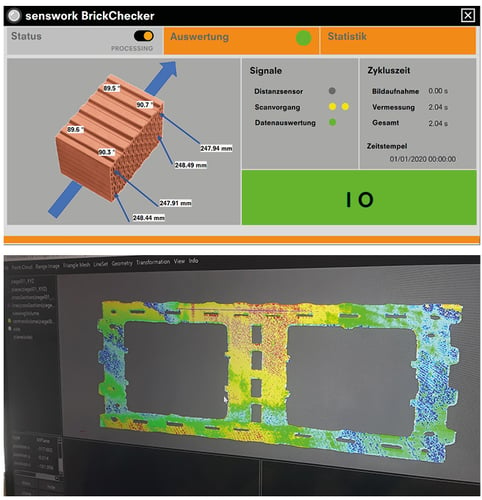

Intelligent evaluation software

- Automatic good/bad analysis based on defined tolerances

- Visualization of 3D elevation maps, difference profiles, and deviations

- Easy parameterization of test characteristics and export of measurement data

- Trend data analysis for process optimization

High repeat accuracy and process reliability

- Reproducible measurement results regardless of operator or component position

- Stable measurement performance even with varying brick colors and surface patterns

- Automatic calibration concept for consistently accurate results

Flexible integration

- Adaptable to different brick formats and grinding variants

- Support for different conveyor systems

- Interfaces to PLC, MES, and customer-specific IT systems

Optional error detection

- Identification of grinding errors, flatness deviations, edge damage

- Reduction of scrap and rework

- Feedback of process data to the grinding line for closed-loop approaches

User-friendly interface

- Touch-optimized GUI with intuitive navigation

- Live feedback on measurement results and system status

- Password-protected levels for operators and administrators