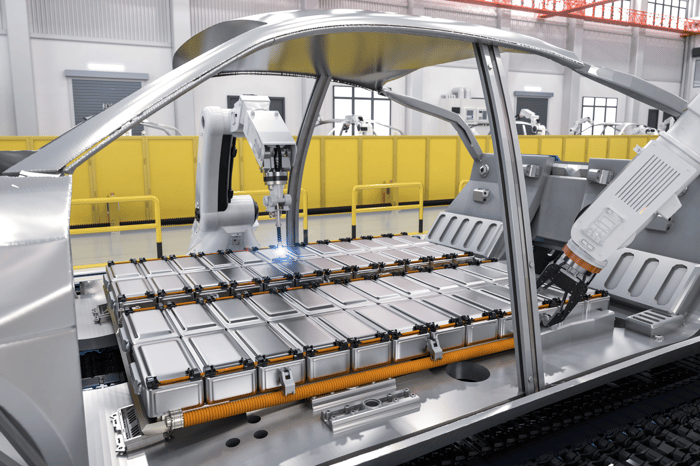

Monitoring the laser welding of hairpins.

ElectrostatorWhen electric motors are assembled, around 160 to 220 hairpins are welded together. With senswork's AI-based inspection system, high-resolution data from the welding points are recorded and evaluated. This is how laser welding can be automated and process quality guaranteed.