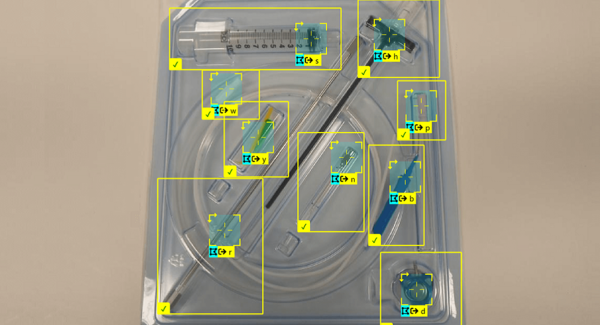

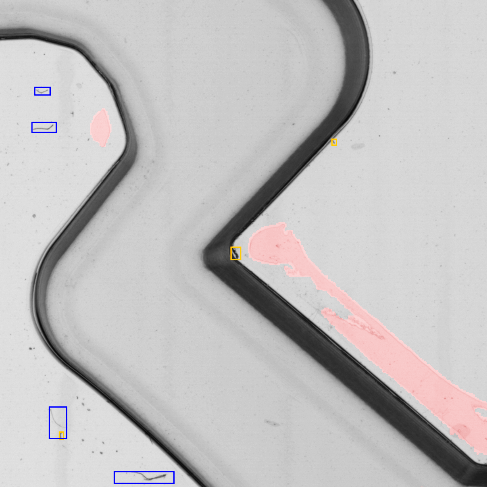

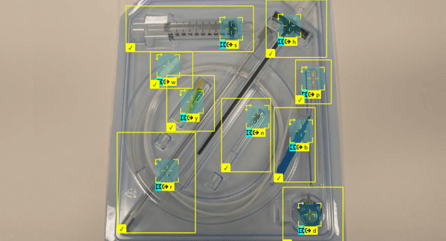

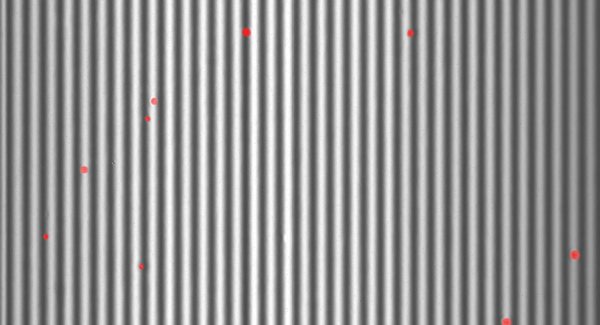

Syringes, cannulas, catheters, bandages

Disposable Medical ProductsQuality assurance involves a wide range of tests, including the inspection of physical properties and functions. These tests ensure that each disposable product is reliable and meets the requirements for sterility and handling, which is essential for successful medical care. This includes checking the production of syringes, cannulas, catheters or bandages.