Automated FOSB Quality Control

Application and Solution

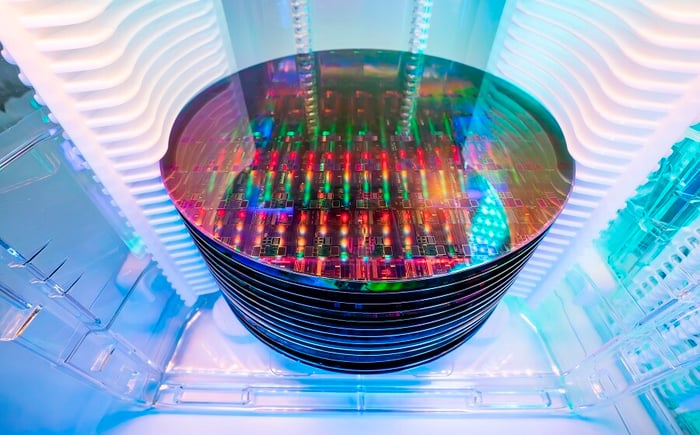

In semiconductor production, safe and efficient packaging is essential, especially when handling sensitive wafers. To ensure error-free packaging of FOSBs (Front Opening Shipping Boxes), our automation partners rely on inspection technology from senswork. This fully automatically checks the assembly of all attached parts, the correct positioning of the wafers (cross-slot test) and the correct printing of the labels.

A highly developed inspection system ensures seamless quality control. Packaging is carried out under cleanroom conditions, with modern robots handling the FOSBs. This automation solution not only reduces errors and waste, but also increases process reliability and efficiency.

Characteristics

- Automatic detection and inspection of the correct attachment of add-on parts to the FOSB

- Checking for the presence of all wafers and for possible misplacement in the FOSB (cross-slot check)

- Verification of the correct printing of the labels on the FOSB and on the outer packaging with our ZPL Inspector

- Seamless integration into existing packaging lines

Quality control of FOSBs in action

Watch the video to see how senswork's state-of-the-art inspection technology ensures fully automatic packaging and quality inspection of FOSBs.

Advantages