Non-contact measurement with ZFokus from senswork

Topics

3D Inspection

Industries

Cosmetics

Application and Solution

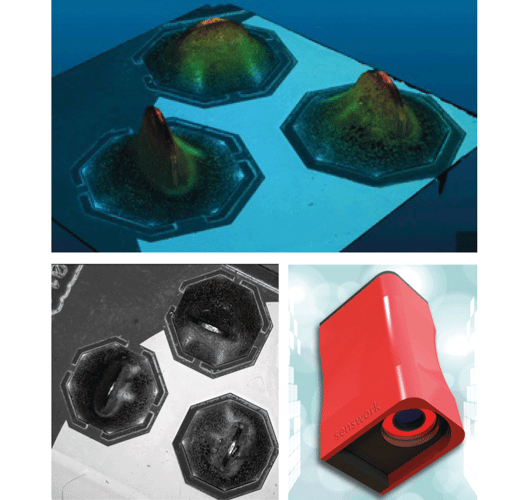

Using solder joint inspection as an example, senswork's ZFokus allows the determination of solder volume, the detection of voids in the solder joint, and the evaluation of the shape of a solder joint.

Tasks

- Determination of the solder volume

- Detection of gaps

- Evaluation of the shape of the solder joint

Benefits