Optical measurement of battery modules without gaps

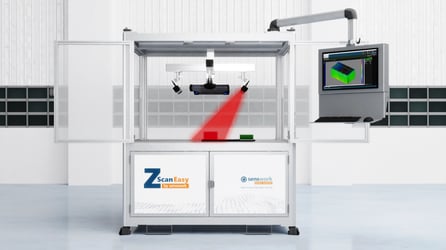

Optical measurement of battery modules without gaps senswork, experts in machine vision systems, will be presenting ZScan ...

Read more

Optical measurement of battery modules without gaps

Optical measurement of battery modules without gaps senswork, experts in machine vision systems, will be presenting ZScan ...

Read more

When the camera becomes the eye

When the camera becomes the eye Everyone has been talking about artificial intelligence (AI) since ChatGPT at the latest. ...

Read more

New brand identity for senswork

New Brand Identity for senswork Burghausen, 08. January 2024 – Machine vision expert senswork has unveiled its new look. In ...

Read more

Manual test station for connector production

senswork presents a manual test station for the inspection of large to very large connector assemblies. The solution is ...

Read more

Artificial Intelligence: Access for All

Burghausen, June 23, 2023 – In the future, everyone in the industry should be able to operate AI tools, set up, and maintain ...

Read more

AI as the silver bullet?

Optical inspection systems have been successfully used in production plants for automated quality assurance for decades. ...

Read more

Making AI visible

Burghausen, February 06, 2023 - The potential that artificial intelligence (AI) already has in industrial image processing ...

Read more

senswork received the “CrefoZert” for the 8th time in a row

senswork has received the CrefoZert for its creditworthiness from Creditreform for the eighth time in a row. Companies that ...

Read more

Visual quality control over long distances

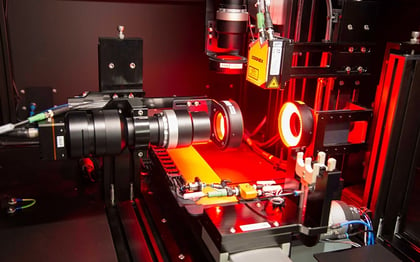

Burghausen, 28. November 2022 – Printed circuit boards and other electronic components can now be inspected from a distance ...

Read more

Transparent LabDisks testable inline

Munich, 11. October 2022 – The detection and inspection of transparent polymer surfaces with the smallest qualitative ...

Read more

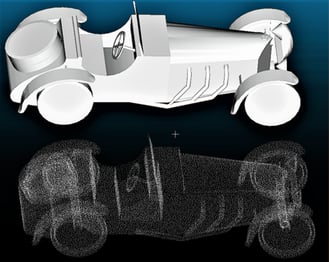

Fast & flexible 3D measurement system for production at Magna

October 6, 2022- Until now, large, geometrically complex objects such as die-cast aluminum parts for the automotive industry ...

Read more

BayBG invests in senswork

Burghausen, 10. August 2022 – Founded in 2011, senswork GmbH, an expert in industrial image processing and optical ...

Read more

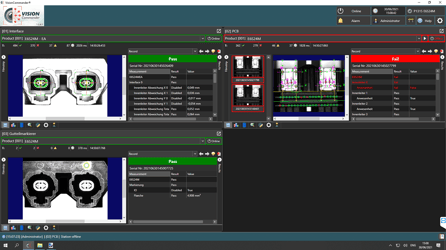

senswork introduces VisionCommander® Gen V1.5

Burghausen, 04. July 2022 – With the introduction of the new generation of VisionCommander® machine vision software, ...

Read more

AI in electric motor manufacturing

Burghausen, 07 June 2022 – The KIKoSA project at Friedrich-Alexander-Universität Erlangen-Nürnberg aims to monitor and ...

Read more

Turnkey manual test station for the pre-series production of connector assemblies

Before a product goes into series production, it must be extensively tested in order to detect and eliminate any product ...

Read more

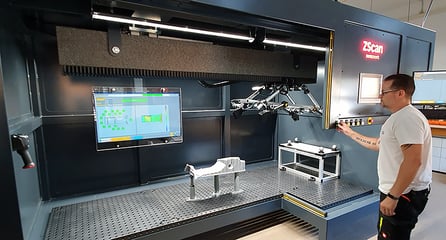

ZScan at the Control: Production-related 3D inspection in seconds

At the Control trade fair in Stuttgart, senswork will be presenting the ZScan 3D measuring system for the first time at the ...

Read more

senswork in the selection for ScaleUp4Europe

senswork is among the last 10 finalists for "ScaleUp4Europe" in the area of "Agile Manufacturing". In the selection process ...

Read more

The measuring room in the production

The new 3D multi-sensor system ZScan from senswork enables the seamless 3D scanning of large components. The modular concept ...

Read more

senswork Inc. becomes Smart Factory Institute's 1st technology partner

senswork Inc. from Johnson City, TN, is the first technology partner of the Smart Factory Institute Chattanooga, which is ...

Read more

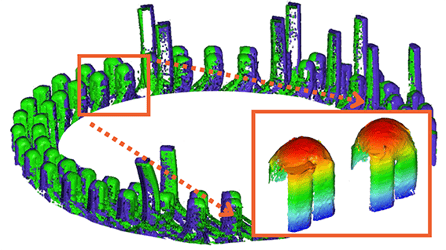

Deep Learning meets 3D Technology

Industrial image processing has reached a new level in understanding image, audio, and text data. 3D point clouds can be ...

Read more

EU Grant "Go International"

In the future, as an expert in industrial image processing, we want to grow together with our customers when it comes to ...

Read more

senswork Inc. | German machine vision expert enters the US Market

Johnson City, TN, 14 September 2021 – senswork, a German based machine vision company, just opened its subsidiary, senswork ...

Read more

Avoid delamination in packaging with Deep Learning

Delamination in composite films can damage the contents of the packaging. One of the reasons for the peeling of foils in ...

Read more

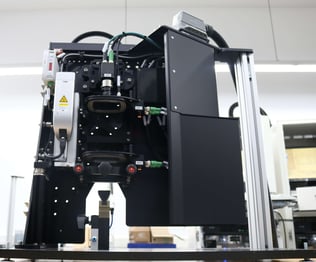

Turnkey camera for quick commissioning in machines

senswork has developed turnkey camera modules that can be installed in machines with little effort. The VisionUnit shows its ...

Read more

High-tech company opens Innovation Lab in Munich

Despite the Covid crisis and lockdown, the Burghausen-based company senswork is growing continuously and is opening an ...

Read more

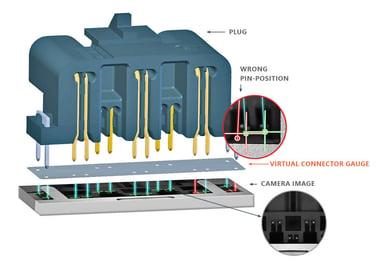

Virtual Connector Gauge: High-precision pin inspection

Plug connections are essential in electrical engineering. Whether in the smartphone, in the car or in production facilities ...

Read more

3D Multi-Sensor Scanner Precisely Positioned

3D Multi-Sensor Scanner Precisely Positioned The 3D multi-sensor system ZScan from senswork scans high-resolution, seamless ...

Read more

senswork is a member of the VDMA

We look forward to a valuable exchange of knowledge and experience with the industry network in order to continue to support ...

Read more